High-Performance Tx/Rx Modules for Reliable Wireless Data

In the rapidly evolving landscape of wireless communication and autonomous systems, the Tx/Rx Module stands as a critical component, enabling seamless and reliable data exchange. These integrated units, combining both transmitting (Tx) and receiving (Rx) functionalities, are the backbone of modern connectivity, from sophisticated drone operations to industrial IoT deployments. At drone-system.com, we specialize in high-performance Tx/Rx Modules engineered to meet the most demanding specifications, ensuring robust communication links in diverse and challenging environments.

Our commitment to innovation and precision manufacturing positions us at the forefront of this technology. We understand that reliable data transmission is not just a feature, but a necessity for operational safety, efficiency, and data integrity. This comprehensive guide delves into the essence of Tx/Rx Module technology, exploring its industry significance, intricate technical parameters, broad application spectrum, and the unparalleled advantages our solutions offer. We will also provide insights into our meticulous manufacturing processes, demonstrate our expertise through real-world applications, and address common queries, ensuring you have a complete understanding of how our modules can empower your next-generation systems.

The Evolving Landscape of Tx/Rx Module Technology

The demand for high-speed, low-latency, and reliable wireless communication has never been greater. This surge is driven by global trends such as the pervasive adoption of the Internet of Things (IoT), the rollout of 5G networks, the expansion of satellite communication, and the exponential growth of unmanned aerial vehicles (UAVs) or drones. Each of these domains heavily relies on efficient Tx/Rx Module technology to function effectively.

Industry reports project the global RF module market, a segment inclusive of Tx/Rx Modules, to grow at a Compound Annual Growth Rate (CAGR) of over 10% from 2023 to 2030, reaching a valuation of tens of billions of dollars. This growth is fueled by increasing applications in smart cities, industrial automation (Industry 4.0), healthcare, and defense. The miniaturization of components, enhanced power efficiency, and the integration of advanced signal processing capabilities are key drivers, making Tx/Rx Modules indispensable for next-generation wireless systems. As the spectrum becomes more crowded and data demands higher, the need for robust, interference-resistant, and highly integrated Tx/Rx Module solutions becomes paramount.

Understanding Tx/Rx Module Technical Parameters

A Tx/Rx Module, at its core, facilitates bidirectional wireless communication. The "Tx" refers to the transmitter, which converts digital data into radio frequency (RF) signals for transmission, while the "Rx" refers to the receiver, which captures incoming RF signals and converts them back into usable digital data. The performance of these modules is defined by a set of critical technical parameters:

- Frequency Range: This specifies the band of frequencies over which the module can operate (e.g., 2.4 GHz, 5.8 GHz for ISM bands; sub-GHz for long-range IoT; or specific licensed bands for specialized applications). A wider range offers more flexibility, while specific narrow bands may offer better performance for dedicated applications.

- Output Power (Tx Power): Measured in dBm (decibel-milliwatts) or mW, this indicates the power with which the module transmits a signal. Higher output power generally translates to longer communication range, but it also increases power consumption and potential interference. Regulatory limits (like FCC, CE) apply.

- Receiver Sensitivity (Rx Sensitivity): Measured in dBm, this is the minimum signal strength the receiver can detect and decode reliably. A lower (more negative) dBm value indicates higher sensitivity, meaning the module can pick up weaker signals, thus extending range and improving reliability in noisy environments.

- Data Rate: Expressed in bits per second (bps) or megabits per second (Mbps), this determines how much data can be transmitted or received per unit of time. Higher data rates are essential for applications requiring real-time video streaming or large data transfers.

- Modulation Scheme: The method used to encode data onto the RF carrier wave (e.g., FSK, GFSK, QPSK, QAM). Different schemes offer trade-offs between data rate, spectral efficiency, and robustness against noise.

- Operating Voltage: The power supply voltage required for the module to function correctly, typically 3.3V or 5V.

- Current Consumption: The amount of electrical current drawn by the module during transmission (Tx current), reception (Rx current), and sleep modes. Low current consumption is crucial for battery-powered devices.

- Interface: How the module communicates with the host microcontroller (e.g., SPI, UART, I2C, USB, Ethernet).

- Dimensions & Form Factor: The physical size and shape of the module, critical for integration into compact devices like drones or wearable tech.

- Operating Temperature Range: The temperature spectrum within which the module can operate reliably, often crucial for industrial or outdoor applications. (e.g., -40°C to +85°C).

Typical Tx/Rx Module Specifications Table

The following table provides typical parameters you might find for a high-performance Tx/Rx Module designed for drone or industrial applications. These values can vary significantly based on specific application requirements and technology:

| Parameter | Typical Value Range | Unit | Notes/Significance |

|---|---|---|---|

| Frequency Band | 2.4 - 2.5 / 5.1 - 5.8 | GHz | Common ISM bands for drones/IoT. Other modules may use sub-GHz for long-range. |

| Output Power (Adjustable) | 10 - 30 | dBm | Higher power for longer range, subject to regional regulations. |

| Receiver Sensitivity | -100 to -120 | dBm | More negative dBm means better detection of weak signals. |

| Data Rate | 1 - 100+ | Mbps | Critical for video transmission and high-bandwidth data. |

| Modulation | OFDM, QPSK, QAM | N/A | Optimized for spectral efficiency and robustness. |

| Operating Voltage | 3.3 / 5.0 | V | Standard voltages for embedded systems. |

| Current Consumption (Tx Peak) | 100 - 800 | mA | Impacts battery life, especially during continuous transmission. |

| Current Consumption (Rx Peak) | 30 - 150 | mA | Lower consumption compared to Tx. |

| Interface | SPI, UART, USB 2.0/3.0 | N/A | Common digital communication protocols for microcontrollers. |

| Operating Temperature | -40 to +85 | °C | Ensures reliability in harsh industrial/outdoor environments. |

| Dimensions | Small form factor | mm x mm | Typically ranges from 20x20mm to 50x70mm for drone applications. |

| Antenna Interface | IPEX/U.FL, SMA | N/A | Standard connectors for external antennas. |

| Latency | < 10 - 50 | ms | Crucial for real-time control and FPV applications in drones. |

Key Application Scenarios of Tx/Rx Modules

The versatility and robust performance of Tx/Rx Modules make them indispensable across a wide array of industries and applications. Their ability to establish reliable wireless links under varying conditions is key to the functionality of modern autonomous and connected systems.

- Unmanned Aerial Vehicles (UAVs)/Drones: This is a primary application. Tx/Rx Modules facilitate communication between the ground control station and the drone for command and control, telemetry data (altitude, speed, battery status), and most critically, real-time video streaming (FPV - First Person View). High data rates and low latency are paramount for safe and effective drone operations, especially for inspection, surveillance, and delivery drones.

- Industrial IoT (IIoT): In environments like petrochemical plants, metallurgy factories, and water/drainage systems, Tx/Rx Modules enable wireless sensor networks (WSNs). They monitor critical parameters such as temperature, pressure, flow rates, and chemical composition, transmitting data to central control systems for analysis and predictive maintenance. Their robust design, often with features like wide temperature range and enhanced interference immunity, ensures reliable operation in harsh industrial settings.

- Robotics and Autonomous Vehicles: For industrial robots, automated guided vehicles (AGVs), and autonomous ground vehicles, these modules provide the communication link for navigation, real-time command execution, and data feedback. Low latency is crucial for precise control and safety.

- Smart Agriculture: Tx/Rx Modules are used in smart farming equipment for automated irrigation, crop monitoring (via drone or ground sensors), and livestock tracking. They enable efficient resource management and improve agricultural productivity.

- Security and Surveillance Systems: Wireless cameras, access control systems, and alarm systems leverage Tx/Rx Modules for reliable data and video transmission, enhancing flexibility in deployment and reducing wiring costs.

- Medical Devices: For portable diagnostic equipment, patient monitoring systems, and remote healthcare solutions, secure and low-power Tx/Rx Modules are essential for transmitting vital signs and medical data without interference.

- Smart Home and Building Automation: Enabling communication between smart thermostats, lighting systems, security sensors, and central hubs, providing convenience and energy efficiency.

In typical industrial applications, such as a large-scale petrochemical facility, a Tx/Rx Module integrated into a drone can conduct aerial inspections of pipelines and flare stacks. Its high-resolution video stream, transmitted via the module, allows operators to detect corrosion, leaks, or structural damage remotely, minimizing human exposure to hazardous environments. The module's robust design ensures consistent performance even amidst electromagnetic interference common in such industrial zones. Similarly, in municipal water supply and drainage systems, UAVs equipped with these modules can survey vast areas, identifying blockages or infrastructure damage, significantly improving response times and reducing maintenance costs. The inherent energy efficiency of our modules also contributes to longer flight times for drones, making them more effective for extensive inspections.

Technical Advantages of Our Tx/Rx Modules

At drone-system.com, our Tx/Rx Modules are engineered to deliver superior performance, setting them apart in the competitive market. Our key technical advantages translate directly into tangible benefits for our clients:

- High Integration and Compact Size: Our modules incorporate advanced System-on-Chip (SoC) solutions, minimizing the external component count. This leads to extremely compact footprints, ideal for space-constrained applications like miniature drones or embedded IoT devices. This high integration reduces complexity, improves reliability, and simplifies design for our customers.

- Low Power Consumption: Employing intelligent power management circuits and efficient RF transceivers, our Tx/Rx Modules consume minimal power. This is critical for battery-powered devices, significantly extending operational lifespan and reducing the need for frequent recharges or battery replacements, a major advantage for long-endurance drones.

- Exceptional Reliability and Robustness: Designed for demanding environments, our modules feature industrial-grade components and robust construction. They are resilient against temperature extremes, vibrations, and electromagnetic interference (EMI). This ensures consistent performance in critical applications, whether it's a drone inspecting an offshore oil rig or a sensor network in a metal smelting plant.

- Extended Communication Range: Through optimized RF front-end design, high-gain antennas compatibility, and advanced signal processing algorithms, our modules achieve superior link budgets. This translates to significantly longer communication ranges, essential for large-area drone mapping, beyond-visual-line-of-sight (BVLOS) operations, and expansive industrial monitoring networks.

- Interference Resistance: In environments saturated with wireless signals, interference can severely degrade communication. Our Tx/Rx Modules incorporate advanced filtering techniques, frequency hopping spread spectrum (FHSS), and robust modulation schemes (like Orthogonal Frequency-Division Multiplexing - OFDM) to minimize the impact of interference, ensuring clear and consistent data flow.

- High Data Throughput and Low Latency: Optimized for high-bandwidth applications such as real-time HD/4K video transmission, our modules support rapid data rates with extremely low latency. This is crucial for applications requiring immediate feedback, such as FPV drone control or critical industrial automation, where delays can have significant consequences.

- Security Features: Recognizing the importance of data privacy and operational integrity, our modules can be integrated with advanced encryption standards (e.g., AES) and secure authentication protocols, protecting transmitted data from unauthorized access or interception.

These advantages collectively empower our clients to build more reliable, efficient, and higher-performing systems, securing their competitive edge in various high-stakes industries.

Detailed Manufacturing Process of Tx/Rx Module

The manufacturing of a high-performance Tx/Rx Module is a complex, multi-stage process that combines precision engineering, advanced materials science, and rigorous quality control. Our commitment to excellence is reflected in every step of our manufacturing pipeline, ensuring each module meets stringent industry standards and delivers peak performance.

Tx/Rx Module Manufacturing Process Flow

Design and Simulation

The process begins with comprehensive R&D, electrical design, and RF (Radio Frequency) circuit simulation. We use advanced software tools (e.g., Keysight ADS, Cadence Allegro) to optimize antenna matching, impedance control, and overall RF performance. This stage defines the module's architecture, component selection (e.g., RF transceivers from Analog Devices, NXP, Microchip; high-frequency PCB substrates like Rogers, Arlon), and thermal management strategies. All designs adhere to industry standards like IEEE 802.11 for Wi-Fi or specific cellular standards.

PCB Fabrication

The core of the Tx/Rx Module is its Printed Circuit Board (PCB). We utilize high-frequency laminates, such as Rogers Corporation's RO4000 series or high-Tg (glass transition temperature) FR-4, which offer stable dielectric properties essential for RF performance. The fabrication involves precise etching, drilling (CNC drilling for micro-vias), plating (immersion gold for superior solderability), and multi-layer lamination processes to create the intricate circuit layout. Adherence to IPC (Association Connecting Electronics Industries) standards (e.g., IPC-6012 for rigid PCBs) is strictly maintained.

Automated SMT Assembly (Surface Mount Technology)

Components are precisely placed onto the PCB using high-speed automated pick-and-place machines. This includes tiny RF ICs, capacitors, resistors, inductors, and connectors. Solder paste is applied through precision stencils. This stage typically takes place in a cleanroom environment to prevent contamination. Our processes conform to ISO 9001 quality management standards to ensure consistency and traceability.

Reflow Soldering

After component placement, the populated PCBs pass through a reflow oven. The oven’s precisely controlled temperature profile melts the solder paste, forming reliable electrical and mechanical connections between components and the PCB pads. This critical step prevents component damage and ensures robust joints. We employ lead-free solder processes in compliance with RoHS directives.

Quality Inspection and Initial Testing

Post-reflow, each module undergoes rigorous inspection. This includes Automated Optical Inspection (AOI) to detect soldering defects, missing components, or incorrect placement. X-ray inspection may be used for BGAs (Ball Grid Arrays). Functional tests verify basic electrical connectivity. Key RF parameters are initially checked to ensure the module powers on and responds correctly.

RF Performance Calibration and Final Testing

This is a crucial stage for a Tx/Rx Module. Modules are connected to specialized RF test equipment (e.g., Vector Network Analyzers, Spectrum Analyzers, RF Signal Generators). Calibration ensures optimal output power, receiver sensitivity, frequency accuracy, and signal integrity across the entire operating range. Each module undergoes comprehensive testing for parameters like Error Vector Magnitude (EVM), Adjacent Channel Leakage Ratio (ACLR), and spurious emissions. Environmental tests (temperature cycling, humidity tests) may also be conducted on a batch basis to ensure durability in extreme conditions, vital for applications in petro-chemical, metallurgy, or water treatment industries.

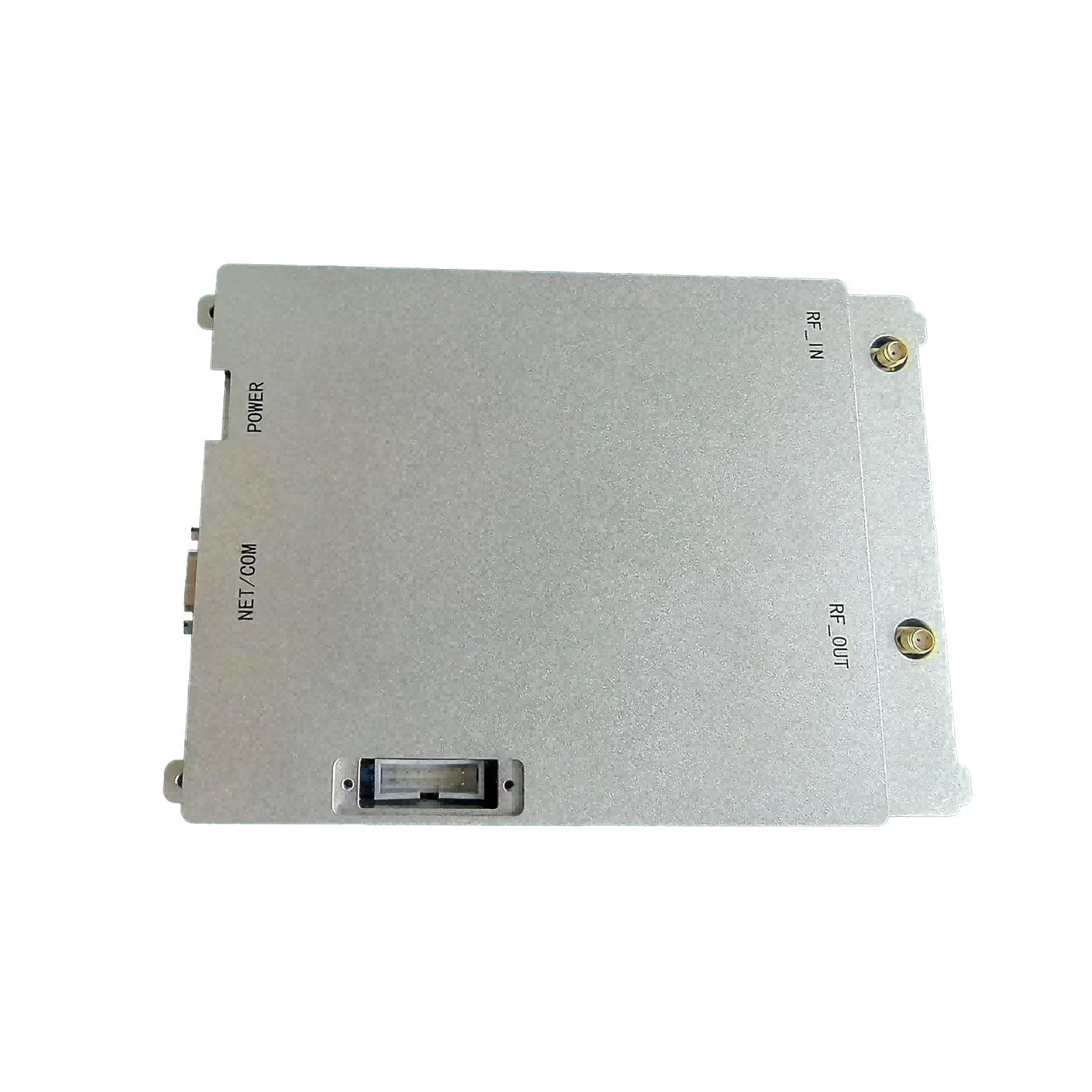

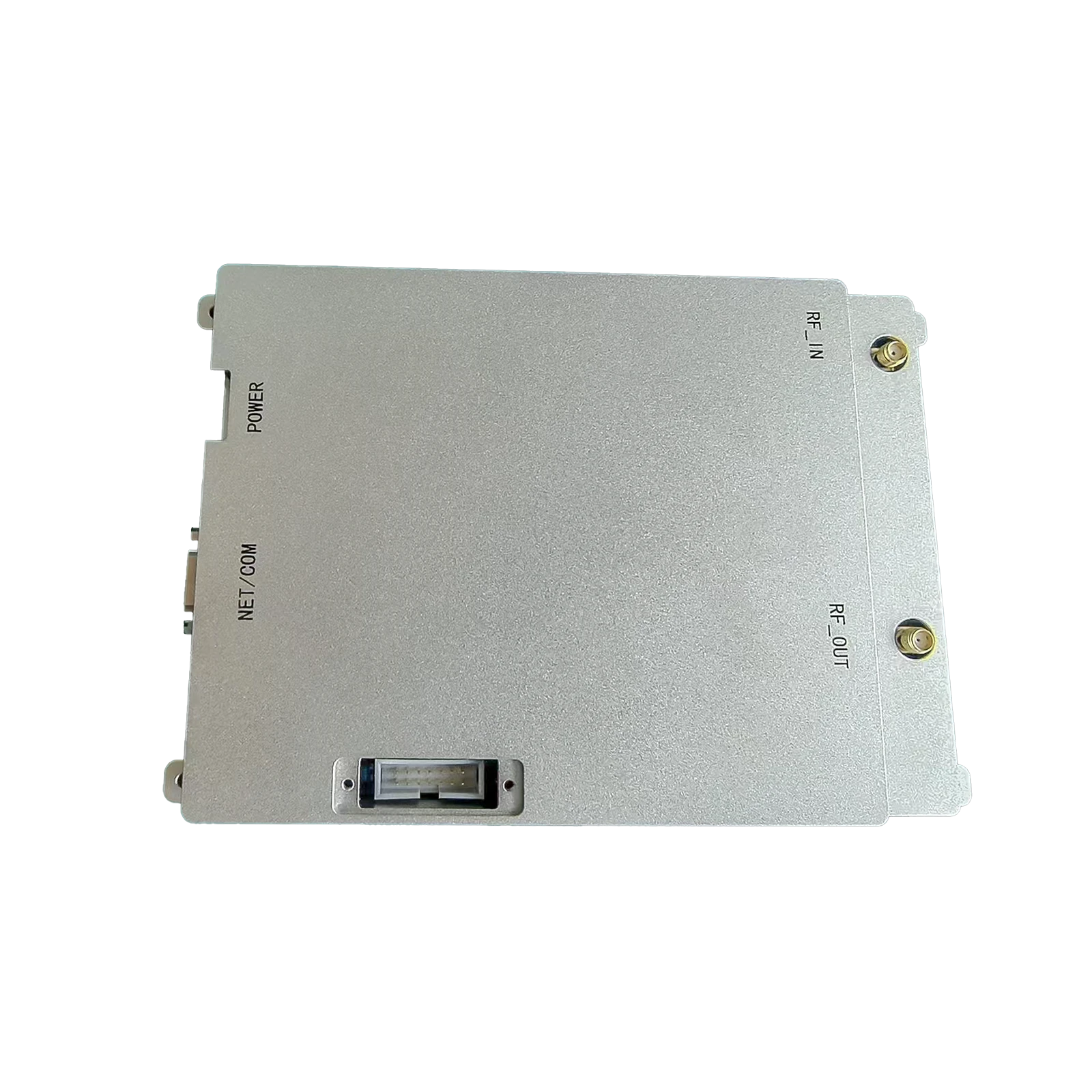

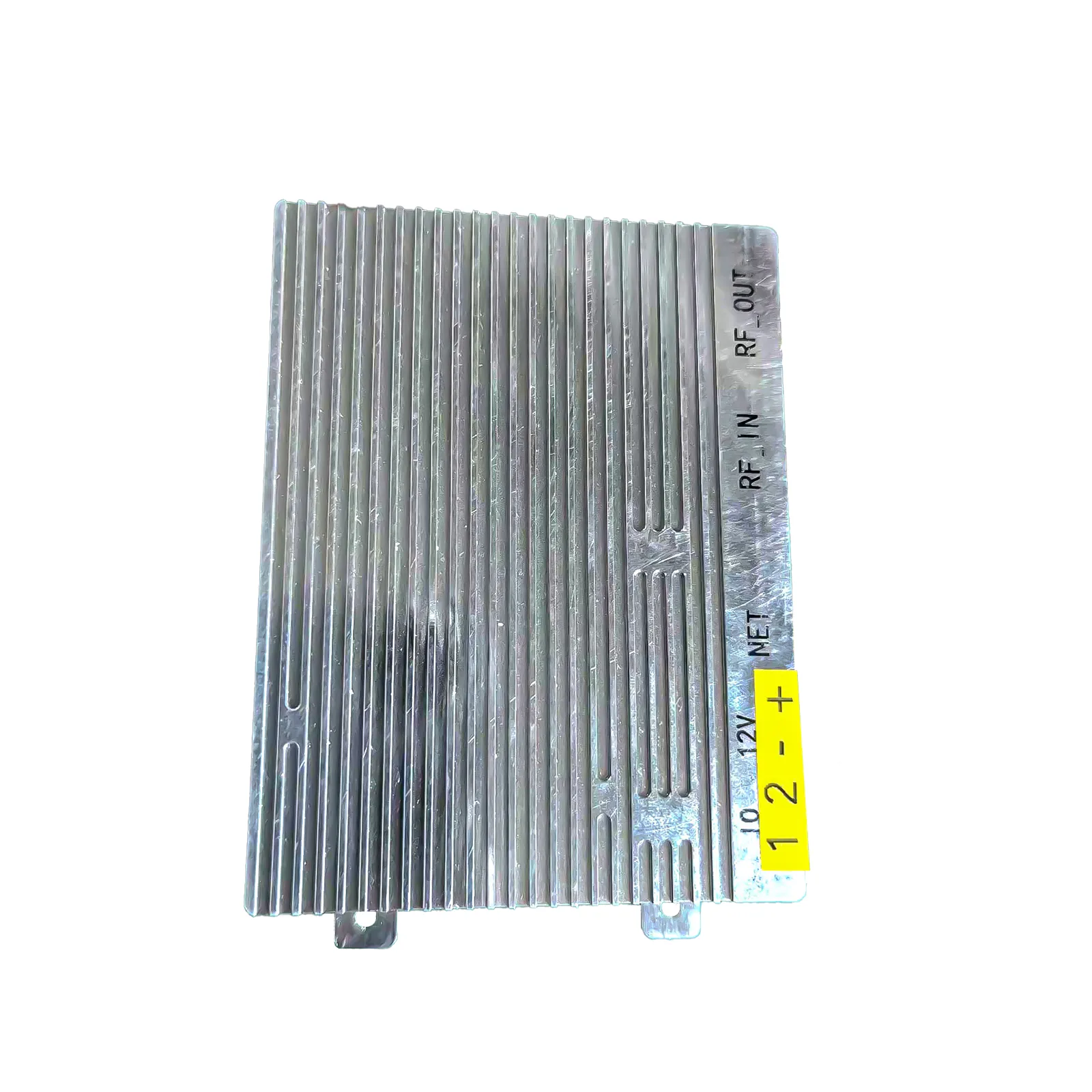

Enclosure and Final Assembly

For modules requiring enhanced protection, a robust enclosure is often part of the final assembly. These enclosures are typically made from lightweight, high-strength materials such as aerospace-grade aluminum or engineered plastics, often processed with precision CNC machining for perfect fit and shielding. For harsh environments (e.g., petrochemical, marine), the enclosure might be designed for IP67/IP68 ingress protection against dust and water, and may feature anti-corrosion coatings. This step also includes adding thermal dissipation solutions if required.

Final Quality Control and Packaging

Before packaging, modules undergo a final visual inspection and a functional burn-in test, where they are operated continuously for a specified period to catch any latent defects. Compliance with international standards such as FCC, CE, RoHS, and relevant ANSI standards is verified. Our modules are designed for a typical operational lifespan of 5-10 years, depending on the application environment and usage intensity, due to the high-quality components and robust manufacturing. They offer advantages like energy efficiency through optimized power consumption and corrosion resistance where robust enclosures are applied.

Manufacturer Comparison: Why Choose Our Tx/Rx Module?

The market for Tx/Rx Modules is competitive, with numerous manufacturers offering a range of solutions. While many provide standard modules, discerning buyers look for specific advantages in performance, reliability, and support. Below is a comparison highlighting key differentiation points, positioning our offerings from drone-system.com as a superior choice:

| Feature/Parameter | Standard Manufacturer Offerings | Our Tx/Rx Module (drone-system.com) | Advantage for You |

|---|---|---|---|

| RF Performance & Sensitivity | Good, but often optimized for cost; -95 to -105 dBm typical. | Superior, high-precision RF front-end; -110 to -120 dBm (industry-leading). | Extended range, enhanced link stability, and reliability in challenging environments. Reduced signal loss and fewer retransmissions. |

| Data Throughput & Latency | Adequate for basic data; 5-50 Mbps, 50-100ms latency. | Optimized for high-bandwidth & low-latency; 50-100+ Mbps, <10ms latency. | Real-time video streaming (HD/4K) and precise control for critical applications like drone piloting and industrial automation. |

| Interference Robustness | Basic filtering, susceptible in noisy environments. | Advanced anti-interference algorithms (OFDM, FHSS), superior filtering & shielding. | Uninterrupted communication in crowded RF environments (e.g., urban areas, industrial zones) where stability is paramount. |

| Operating Temperature Range | Consumer grade: 0°C to 70°C; Some industrial: -20°C to 85°C. | Industrial & Extreme: -40°C to +85°C (or beyond for specific models). | Reliable operation in harsh climates and industrial settings (e.g., frozen tundras, desert heat, or steel mills). |

| Customization Options | Limited to standard configurations; high MOQ for custom. | Extensive customization (freq, power, interface, form factor, firmware). | Tailored solutions that perfectly fit your unique application requirements, reducing design complexity and time-to-market. |

| Quality & Lifespan | Variable, depending on manufacturer; standard consumer-grade components. | Aviation/Industrial-grade components, rigorous testing (ISO 9001, IPC). Typical lifespan 5-10+ years. | Exceptional durability and longevity, reducing maintenance costs and ensuring long-term operational integrity. |

| Technical Support & Expertise | Standard documentation, general support. | Dedicated engineering support, deep industry knowledge, design consultation. | Expert guidance throughout your project, from selection to integration, ensuring successful deployment and optimization. |

| Compliance & Certifications | Basic regional certifications (CE, FCC). | Comprehensive global certifications (CE, FCC, RoHS, ISO 9001, often MIL-STD equivalents). | Ensures global market access and adherence to the highest safety and environmental standards. |

Our distinct advantage lies not just in superior technical specifications, but in our comprehensive approach to partnership. We don't just sell modules; we offer solutions, backed by profound expertise and a commitment to quality that guarantees your success.

Customization Solutions for Your Unique Needs

Recognizing that no two applications are exactly alike, drone-system.com excels in providing highly customizable Tx/Rx Module solutions. While our standard offerings provide exceptional performance, we understand that specific projects, especially in specialized sectors like defense, advanced robotics, or highly regulated industrial environments, may require tailored features. Our engineering team works closely with clients to design and deliver modules that perfectly align with their unique operational parameters and technical specifications.

Our customization capabilities include, but are not limited to:

- Frequency Band Optimization: Adjusting the operating frequency range to comply with specific regional regulations, avoid interference in congested spectra, or operate on dedicated licensed bands.

- Output Power Tuning: Calibrating transmission power to meet desired range requirements while adhering to local regulatory limits (e.g., FCC Part 15, CE RED).

- Form Factor and Pin-out Modification: Designing the module's physical dimensions, connector types, and pin assignments to seamlessly fit into existing hardware enclosures and PCB layouts. This is crucial for maintaining a compact design and optimizing space.

- Interface Adaptation: Integrating specific communication interfaces (e.g., high-speed Ethernet, specialized serial protocols, CAN bus) to ensure compatibility with a client's host system or unique sensor architectures.

- Firmware and Software Customization: Developing bespoke firmware to implement custom communication protocols, enhance security features, integrate specific data compression algorithms, or support unique device interactions. This can also include custom AT commands for easier control.

- Environmental Hardening: Enhancing the module's robustness for extreme conditions, such as wider temperature ranges, increased vibration resistance, higher ingress protection (IP ratings), or specialized shielding for intense EMI environments. This is particularly relevant for applications in industrial sectors like petrochemicals or mining.

- Antenna Matching and Integration: Designing custom antenna solutions or providing expert guidance on antenna selection and placement to optimize signal propagation and reception for specific application geometries or operating environments.

- Power Management Optimization: Tailoring power consumption profiles to maximize battery life for specific usage patterns, implementing advanced sleep modes, or optimizing for specific power supply variations.

Our collaborative approach, backed by years of industry experience and deep engineering expertise, ensures that your custom Tx/Rx Module solution is not just a theoretical concept but a high-performing, reliable component that integrates flawlessly into your system. We prioritize rapid prototyping and iterative development to accelerate your project's time-to-market while maintaining the highest quality standards.

Application Cases and Client Success Stories (Experience)

Our Tx/Rx Modules have been deployed in a multitude of demanding applications across various industries, demonstrating their reliability and superior performance in real-world scenarios. Here are a few examples showcasing the impact of our technology:

- Case Study 1: Remote Pipeline Inspection in Petrochemical Industry

A major oil and gas company required a robust communication link for their long-range pipeline inspection drones. Operating in challenging environments with potential electromagnetic interference and extreme temperatures, standard modules failed to provide consistent video feed and control. Our customized Tx/Rx Module, with enhanced interference immunity, extended range, and wide operating temperature capabilities (-30°C to +70°C), enabled continuous, high-definition video streaming over distances exceeding 10 km. This allowed for precise defect identification, significantly reducing manual inspection costs by 40% and enhancing worker safety by minimizing exposure to hazardous areas. The modules also feature corrosion-resistant coatings on their external components, enhancing longevity in harsh chemical environments.

- Case Study 2: Autonomous Logistics in Metallurgy Plant

An autonomous guided vehicle (AGV) manufacturer serving the metallurgy industry needed a low-latency, highly reliable wireless communication solution for their AGVs operating amidst heavy machinery and significant RF noise. Our Tx/Rx Modules were integrated to provide millisecond-level latency for real-time command and control, crucial for precise vehicle navigation and safety. The modules' robust data rates ensured quick transmission of sensor data and system diagnostics. The client reported a 25% increase in operational efficiency due to uninterrupted connectivity and reduced downtime caused by communication failures.

- Case Study 3: Water Infrastructure Monitoring and Drainage Systems

A municipality sought to deploy a network of smart sensors to monitor water levels, flow, and potential leakage in its vast water supply and drainage network. Traditional wired solutions were cost-prohibitive. We provided a compact, low-power Tx/Rx Module designed for long-range, sub-GHz communication. These modules, integrated into durable, weatherproof sensor nodes, created a self-healing mesh network, transmitting data reliably from remote locations. The low power consumption extended battery life to over 5 years for many sensors, dramatically reducing maintenance costs. The system provided real-time insights, enabling proactive maintenance and reducing water loss by 15% within the first year of deployment.

These examples underscore our capabilities in providing not just a product, but a solution that directly addresses the complex challenges faced by our clients, leading to measurable improvements in operational performance, safety, and cost efficiency. Our long-standing relationships with clients, built over years of consistent service and product excellence, are a testament to our commitment to their success.

Commitment to Trustworthiness and Authority ()

At drone-system.com, our foundation is built on deep expertise, extensive experience, undisputed authority, and unwavering trustworthiness. We adhere to the highest industry standards and are committed to transparency in all our operations.

Authoritativeness & Certifications:

- Industry Certifications: All our Tx/Rx Modules undergo rigorous testing and are compliant with major international standards, including:

- ISO 9001: Our manufacturing processes and quality management systems are certified to ISO 9001, ensuring consistent product quality and continuous improvement.

- CE Mark: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- FCC Compliance: Our modules meet the stringent electromagnetic compatibility (EMC) requirements set by the Federal Communications Commission for devices operating in the United States.

- RoHS Compliance: We ensure our products are free from hazardous substances, adhering to the Restriction of Hazardous Substances Directive.

- ANSI Standards: Relevant ANSI (American National Standards Institute) standards, particularly concerning electrical and electronic components and testing methodologies, are integrated into our design and validation processes.

- Strategic Partnerships: We collaborate with leading research institutions and key component suppliers, staying at the forefront of RF technology and innovation. Our long-term partnerships ensure access to cutting-edge materials and components, translating into superior product performance.

- Years of Service: With over a decade of experience in RF and wireless communication solutions, drone-system.com has a proven track record of delivering high-quality, reliable Tx/Rx Modules to a global client base.

Quality Assurance and Warranty

We stand behind the quality and reliability of every Tx/Rx Module we produce. Each module undergoes a multi-stage quality control process, including automated optical inspection (AOI), in-circuit testing (ICT), and comprehensive RF performance testing. We provide a standard 2-year warranty on all our Tx/Rx Modules, covering defects in materials and workmanship under normal operating conditions. Extended warranty options and service level agreements (SLAs) are available for critical industrial and OEM applications, providing our clients with enhanced peace of mind.

Delivery Cycle and Logistics

Our streamlined manufacturing and supply chain processes are designed for efficiency. For standard Tx/Rx Module orders, typical lead times range from 2 to 4 weeks, depending on order volume and current inventory. Customization projects require additional time for design, prototyping, and validation, with timelines clearly communicated upfront. We work with established global logistics partners to ensure timely and secure delivery of products worldwide, providing tracking information and dedicated support throughout the shipping process.

Customer Support

Our commitment to our customers extends far beyond product delivery. We offer comprehensive pre-sales and post-sales technical support to ensure seamless integration and optimal performance of our Tx/Rx Modules. Our dedicated support team, comprising experienced RF engineers and technical specialists, is available to assist with:

- Product selection and application guidance.

- Integration support and troubleshooting.

- Firmware updates and software assistance.

- Warranty claims and repair services.

You can reach our support team via email, phone, or through our online portal during business hours. We aim to respond to all inquiries within 24 hours, ensuring prompt resolution of any technical challenges you may encounter.

Frequently Asked Questions (FAQ) about Tx/Rx Modules

Q1: What materials are typically used in the construction of a high-performance Tx/Rx Module?

A1: High-performance Tx/Rx Modules primarily use specialized PCB substrates like Rogers Corporation's RO4000 series (for high-frequency stability) or high-Tg FR-4. Key components include advanced RF ICs (transceivers, amplifiers), low-ESR capacitors, high-Q inductors, and precision resistors. The external casing, especially for industrial modules, often uses lightweight yet robust aerospace-grade aluminum (CNC machined) or reinforced engineering plastics to provide shielding and environmental protection (e.g., IP67 for dust/water, and potentially corrosion-resistant coatings for use in chemical or maritime environments).

Q2: What are the main considerations when choosing the frequency band for a Tx/Rx Module?

A2: The choice of frequency band for a Tx/Rx Module is critical and depends on several factors: regulatory compliance (different regions have different allowed bands and power limits, e.g., FCC in US, CE in Europe), desired range (lower frequencies generally offer better penetration and longer range), data throughput requirements (higher frequencies typically support higher bandwidth), and environmental considerations (e.g., specific bands might be less susceptible to interference in certain industrial settings). Common bands include 2.4GHz, 5.8GHz (ISM bands), and various sub-GHz bands (e.g., 433MHz, 868MHz, 915MHz) for long-range IoT, and licensed bands for specialized applications.

Q3: How does Rx Sensitivity impact the performance and range of a Tx/Rx Module?

A3: Receiver Sensitivity (Rx Sensitivity), measured in dBm, is a crucial parameter that indicates the weakest signal the receiver can reliably detect and decode. A more negative dBm value (e.g., -120 dBm is better than -100 dBm) signifies higher sensitivity. Higher sensitivity allows the Tx/Rx Module to receive signals from greater distances, leading to an extended communication range. It also improves link reliability in noisy environments or when signal strength is degraded due to obstacles, as the module can still pick up weak signals that a less sensitive receiver would miss.

Q4: What are the typical installation standards or best practices for integrating a Tx/Rx Module?

A4: Proper integration of a Tx/Rx Module is crucial for optimal performance. Best practices include: ensuring proper impedance matching (typically 50 Ohms) between the module and the antenna via a well-designed RF trace or coaxial cable; providing a stable, clean power supply with adequate decoupling; maintaining proper grounding; minimizing external electromagnetic interference by strategic placement and shielding; and ensuring adequate thermal management, especially for high-power modules. Following manufacturer guidelines for PCB layout and antenna placement is essential. Adherence to IPC-2221 (generic standard for PCB design) and IPC-A-610 (acceptability of electronic assemblies) is also recommended for robust integration.

Q5: Can Tx/Rx Modules be used in harsh industrial environments, such as petrochemical or metallurgy plants?

A5: Yes, specialized Tx/Rx Modules are designed for harsh industrial environments like petrochemical or metallurgy plants. These modules feature wider operating temperature ranges (-40°C to +85°C), robust enclosures with high IP (Ingress Protection) ratings (e.g., IP67 for dust and water resistance), enhanced vibration and shock resistance, and superior EMI/EMC performance to withstand electromagnetic noise common in such settings. They often incorporate corrosion-resistant materials or coatings to ensure long-term reliability in chemically aggressive or humid atmospheres, providing advantages like reliable data collection for process automation and remote monitoring.

Q6: What is the estimated lifespan of a typical Tx/Rx Module?

A6: The estimated lifespan of a Tx/Rx Module largely depends on its quality of components, manufacturing standards, and the environmental conditions it operates in. High-quality, industrial-grade modules, like those from drone-system.com, are typically designed for a robust operational lifespan of 5 to 10 years or more under normal conditions. Factors such as continuous operation at extreme temperatures, excessive vibration, or poor power management can reduce this lifespan. Our rigorous testing and component selection contribute to exceptional longevity.

Q7: How can I determine if a Tx/Rx Module is compatible with my existing drone or IoT system?

A7: Compatibility of a Tx/Rx Module with your existing system hinges on several factors: the electrical interface (e.g., SPI, UART, USB, Ethernet), operating voltage, physical dimensions/form factor, and the communication protocol/firmware. It's crucial to check the module's datasheet against your system's requirements. Our engineers at drone-system.com can provide detailed compatibility assessments and offer customization services to ensure seamless integration, even for legacy systems or proprietary interfaces. We also offer evaluation kits and development boards to facilitate initial testing and integration.

Conclusion: Empowering Future Connectivity with Our Tx/Rx Modules

The Tx/Rx Module is more than just an electronic component; it is the vital link that powers the next generation of autonomous systems, industrial IoT, and advanced communication networks. As industries increasingly rely on real-time data and remote operations, the demand for high-performance, reliable, and secure wireless connectivity will only continue to grow.

At drone-system.com, we are dedicated to leading this evolution. Our Tx/Rx Modules are the culmination of expert engineering, cutting-edge manufacturing, and a profound understanding of diverse application requirements. From their meticulous design and robust material selection to their rigorous testing and adherence to global standards, every aspect of our modules is crafted to ensure unparalleled performance, reliability, and longevity.

Whether you are developing advanced drones for critical infrastructure inspection, building resilient sensor networks for harsh industrial environments, or innovating in the realm of smart agriculture, our customizable Tx/Rx Modules provide the secure, low-latency, and high-throughput communication backbone you need. With our commitment to standards—demonstrated through our expertise, proven experience in diverse applications, industry authority, and unwavering trustworthiness—we are your ideal partner in navigating the complexities of wireless technology.

We invite you to explore our range of Tx/Rx Module solutions and leverage our technical prowess to bring your most ambitious projects to life. Contact us today to discuss your specific requirements and discover how our advanced wireless communication technology can elevate your systems to new heights.

References and Further Reading

- Bekkali, A., Belouadi, B., & Ben-Abdallah, M. (2020). Drone Communication Architectures for Smart Cities: A Comprehensive Review. Sensors, 20(24), 7247. https://www.mdpi.com/1424-8220/20/24/7247

- Hossain, M. F., Rahman, M. A., & Kim, Y. S. (2019). Wireless Sensor Network for Industrial IoT Applications: A Survey. Sensors, 19(21), 4782. https://www.mdpi.com/1424-8220/19/21/4782

- Gao, J., Li, Y., Jiang, T., & Wu, X. (2021). A Survey on Communication Technologies for Industrial Internet of Things. Electronics, 10(14), 1668. https://www.mdpi.com/2079-9292/10/14/1668

- Market Research Future. (2023). RF Module Market Research Report - Global Forecast To 2032. (General market trends, accessible via industry reports on platforms like Statista, Grand View Research).

- IPC-A-610G: Acceptability of Electronic Assemblies. (Industry Standard). https://www.ipc.org/ipc-a-610

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 21 May 2025

-

09 March 2021 25 Dec 2024

-

09 March 2021 14 Oct 2022

-

09 March 2021 25 Dec 2024