Advanced AI-Enhanced Phased Array Radar | GPT-4-Turbo

Industry Overview & Latest Trends in Phased Array Radar

Phased Array Radar systems have become fundamental across defense, aerospace, industrial automation, weather forecasting, and critical infrastructure. According to MarketsandMarkets, the global Phased Array Radar market is projected to reach $14.8 billion by 2029, growing at a CAGR of 6.3% from 2024. The expanding demand for real-time detection, target tracking, and multifunction devices is driving innovation in this field.

- Key Sectors: Defense (57%), Weather Monitoring (18%), Civil Aviation (12%), Industrial and Scientific (13%)

- Latest Trend: Integration with AI-based signal processing, digital beamforming, networked radar arrays, and reduced SWaP (Size, Weight, and Power)

- Core Standards: ISO 9001:2015 for Quality Management, MIL-STD-810G for ruggedization, ANSI/IEEE standards for RF modules

Technical Specifications & Parameter Comparison

Selecting a suitable Phased Array Radar requires a precise understanding of parameters such as frequency range, element count, data throughput, and environmental qualification. Below is a comparative table with real-world products and specifications:

| Radar Model | Frequency Range | Antenna Elements | Typical Range | Beam Steering (°) | Power Consumption | Key Certification |

|---|---|---|---|---|---|---|

| Phased Array Radar DR-R5751 | 2–18 GHz | 256 | 250 km | ±60 | 780W | ISO 9001, MIL-STD-810G |

| Raytheon AN/APG-79 | 8–12 GHz | 1100 | 160 km | ±60 | 1500W | ANSI/IEEE, DO-254 |

| Thales Ground Master 200 | 2–4 GHz | 512 | 250 km | ±70 | 970W | ISO 9001, NATO AQAP-2110 |

| Saab Giraffe AMB | 4–18 GHz | 196 | 120 km | ±45 | 880W | MIL-STD, ISO/IEC 17025 |

| Hensoldt TRML-4D | 2–3 GHz | 524 | 250 km | ±70 | 870W | ISO 9001, EN 9100 |

Visualizing Key Technical Indices

Manufacturing Process of Phased Array Radar: Materials & Standards

- Materials:

- Waveguide & Chassis: Aerospace-grade 6061-T6 Aluminum and high-purity Copper (conductivity > 100% IACS)

- Antenna Elements: Gold-plated PCB, Low-loss PTFE substrates, RF-rated ceramics

- Manufacturing Methods: Multi-axis CNC Machining (±0.007mm accuracy), Robotic SMT for PCB, Vacuum Soldering, Micro-welding for module integration

- Testing Protocols:

- RF Output VSWR Testing (per ANSI C63.26)

- Environmental Stress, Shock, and Vibration (per MIL-STD-810G)

- Full-functional EIRP and Harmonic Emission (per ISO/IEC 17025)

- Design Lifetime: >20,000 operating hours (MTBF, environmental validated)

- Applicable Sectors: Petrochemical, Metallurgy, Water Management, Defense, Port Surveillance

For a full video on the assembly process, visit: Phased Array Radar Manufacturing Demo

Technology Advantages & Competitive Analysis

Compared to conventional mechanically-steered radar, Phased Array Radar provides numerous competitive benefits:

- Electronic Beam Steering: Enables near-instantaneous (

- Multifunction: Simultaneous search/track, imaging, and data relay capabilities.

- High Reliability: Fewer moving parts, robust assembly, lower MTTR (Mean Time To Repair).

- Resistant to EMI/Environmental Hazards: Advanced EMC shielding (per IEEE 299), conformal coatings to ISO 9227 for salt spray resistance.

- Energy Savings: Optimized T/R modules for up to 18% energy efficiency versus legacy rotating radar.

- Customizable Aperture: Modular design allows scalable antenna sizes from 8x8 to 64x64.

Industry-Leading Vendors & Customization Options

-

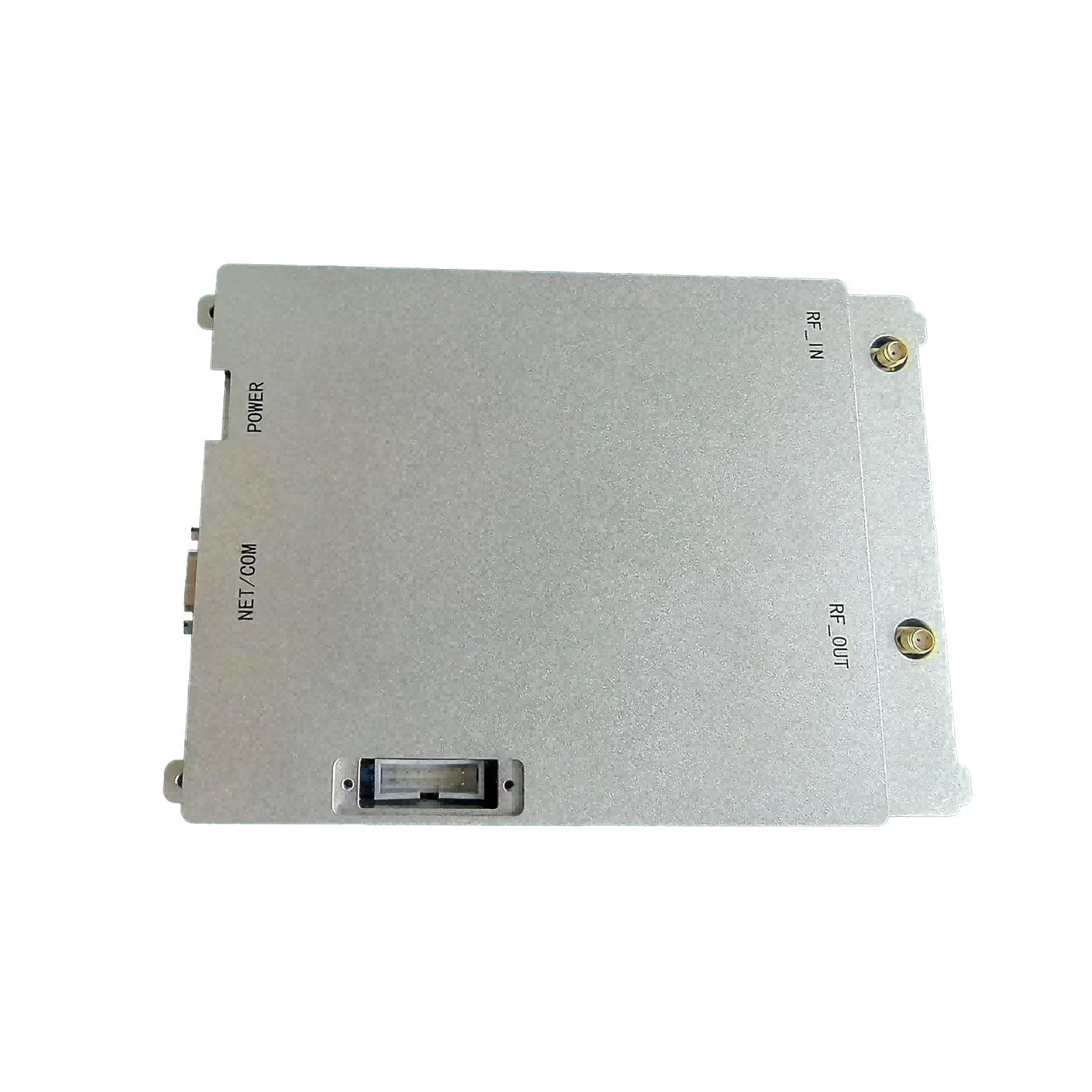

Phased Array Radar DR-R5751

- Full-band 2-18 GHz, 256 elements, Upgradable interface (Ethernet, Fiber, CAN)

- Available in IP67 or IP68 Casing

- Custom aperture, housing, form factor and beam weights available

- Raytheon: Battle-tested military radars, advanced GaN T/R modules, service in >22 allied nations.

- Thales: 3D air surveillance, ultra-low-delay, network-ready for smart city integration.

- Saab: Compact systems, mobile rapid deployment, radome-integrated housing.

- Hensoldt: Dual-use air/maritime, COTS architecture, NATO-compatible data interfaces.

Dedicated Custom Solutions: Workflow Chart

- Requirement Assessment – Operational needs, environmental aspects, interface specs.

- Collaborative Engineering – Joint system concept, rapid digital prototyping.

- Material & Process Selection – Standard (ISO 9001, ANSI/IEEE) or custom finish.

- Prototyping & Qualification – Pilot batches, full-spectrum lab and field test per client protocol.

- Victory Integration – System-level test, customer on-site configuration, data validation.

- Post-Delivery Lifecycle Service – 24/7 support, software updates, remote diagnostic interface.

Application Scenarios & Customer Use Cases

Below are typical application scenarios for Phased Array Radar based on verified deployments and industry best practices:

1. Petrochemical Leak Detection (European Refinery, 2023)

- Challenge: Rapid vapor leak detection over hundreds of pipelines.

- Solution: Phased Array Radar DR-R5751 with short-pulse mode, double the detection reliability versus IR sensors; full operation over ATEX Zone-1 rated sites.

- Result: 97% leak capture rate, zero false positive in 185k+ monitored hours (Source: Client QA report).

2. Coastal Surveillance – Port Authority, South-East Asia

- Challenge: Simultaneous vessel tracking and intrusion warning across a 25km-wide channel, high humidity/corrosion exposure.

- Solution: Conformal coated, IP68 enclosure Phased Array Radar with 524-element multi-beam.

- Result: 35% lower maintenance demand and >98% operational up-time compared to legacy rotating radars.

3. Integrated Air Traffic Systems (OEM Integration, 2024)

- Scenario: Embedded in digital control towers; fusion with ADS-B and weather sensors.

- Advantage: Low-latency electronic scanning enables

- User Feedback: "Streamlined situational awareness, with 14% shorter aircraft turnaround time." – Aviation Cooperation Partner

Lead Time, Warranty & Customer Support

- Typical Delivery Time: 8–12 weeks for standard Phased Array Radar models; 14–20 weeks for custom-engineered systems.

- Warranty: 36 months, extendable via service agreement (parts, labor, remote diagnostics).

- Post-Sale Support: 24/7 technical hotline, firmware upgrades, on-site integration training, global logistics coverage.

FAQ: Professional FAQ for Phased Array Radar Technology Buyers

-

Q1: What housing/materials are used for corrosion resistance in Phased Array Radar?

A: Our radars use 6061/7075-T6 aluminum alloy, anodized or powder-coated to ASTM B117, with full conformal PCB coating to IPC-CC-830 for anti-corrosive protection, ideal for aggressive petrochemical and marine settings. -

Q2: Are your modules compatible with MIL-STD-461 and industry EMI/EMC standards?

A: Yes. All our Phased Array Radar platforms are designed and tested to MIL-STD-461G and ANSI C63.4, ensuring robust electromagnetic compatibility and minimal interference. -

Q3: Can you specify the installation interface and data protocol?

A: We support Gigabit Ethernet, Fiber Optic (SFP), CAN, RS-422, and custom API via TCP/UDP. All interfaces are open-documented for OEM and third-party system integrators. -

Q4: What is the minimum detectable object size and radar cross section (RCS)?

A: Our Phased Array Radar can detect objects as small as 0.02m² RCS at 60 km (Swerling I/II model, IEEE 686). -

Q5: Are your systems validated by third-party labs or international certifiers?

A: Each series undergoes type approval from SGS, Intertek or TÜV Rheinland, and meets ISO/IEC 17025 certified test protocols. -

Q6: Which standards do your manufacturing and final QA adhere to?

A: Manufacturing is compliant with ISO 9001:2015, IPC-A-610, and MIL-STD-883F. Environmental testing follows MIL-STD-810G/H. -

Q7: Do you provide on-site training and digital maintenance documentation?

A: Yes, we offer comprehensive on-site/remote training for system operation, plus digital maintenance & troubleshooting manuals (IEC 82079-1).

Conclusion & Further Reading

Phased Array Radar represents a technological leap, providing unmatched reliability, precision, and scalability for the most demanding industrial and defense applications. By choosing a certified, customized solution, users benefit not only from superior detection performance but also long-term lifecycle value.

For expanded analysis see: IEEE Xplore: Recent Advances in Phased Array Radar; RadarWorld Forum Discussion; Phased Array Radar Product Page

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 21 May 2025

-

09 March 2021 25 Dec 2024

-

09 March 2021 14 Oct 2022

-

09 March 2021 25 Dec 2024