High-Performance Tx/Rx Module: Reliable Wireless Data Transfer

Explore the cutting-edge world of Tx/Rx Module technology – the backbone of modern wireless communication systems. This comprehensive guide delves into industry trends, technical specifications, diverse applications, and the manufacturing excellence that sets leading solutions apart. Discover how these modules are revolutionizing connectivity across various sectors.

The Evolving Landscape of Tx/Rx Module Technology: Industry Trends

The realm of wireless communication is constantly pushing boundaries, driven by an insatiable demand for higher data rates, lower latency, and expanded connectivity. At the core of this evolution lies the Tx/Rx Module – a critical component responsible for converting electrical signals into radio waves for transmission (Tx) and vice versa for reception (Rx). Modern industry trends indicate a significant shift towards:

- Miniaturization and Integration: As devices become smaller and more portable, there's an increasing need for highly integrated Tx/Rx Module solutions that combine multiple functionalities onto a single chip or compact package. This reduces overall system size, weight, and power consumption.

- Higher Frequency Bands: The move towards 5G, 6G, and satellite communication necessitates operation in millimeter-wave (mmWave) and sub-THz bands. This presents challenges in material selection, impedance matching, and thermal management, requiring advanced designs for Tx/Rx Module.

- Enhanced Efficiency and Power Management: With the proliferation of IoT devices and battery-powered systems, energy efficiency is paramount. Modern Tx/Rx Modules are designed to minimize power consumption in both active and standby modes, extending device operational life.

- Adaptive and Cognitive Capabilities: The integration of AI and Machine Learning (ML) is enabling Tx/Rx Modules to dynamically adapt to varying channel conditions, optimize signal quality, and even predict potential interference, leading to more robust and reliable communication.

- Robustness and Reliability for Harsh Environments: From industrial IoT in factories to aerospace applications, Tx/Rx Modules must withstand extreme temperatures, vibrations, and electromagnetic interference (EMI), driving demand for ruggedized designs and specialized materials.

Unpacking the Core: Technical Parameters of Tx/Rx Modules

Understanding the key technical parameters is crucial for selecting the right Tx/Rx Module for any specific application. These parameters define the module's performance characteristics and suitability for various communication standards and environments. Here's a breakdown of essential specifications:

- Frequency Range (GHz): The range of radio frequencies over which the module can effectively transmit and receive signals. This is critical for compatibility with specific communication protocols (e.g., 2.4 GHz for Wi-Fi, 5 GHz for higher-speed Wi-Fi, sub-6 GHz and mmWave for 5G).

- Output Power (dBm): The maximum power at which the transmitter can output a signal. Higher output power generally translates to longer communication range, but also higher power consumption and potential for interference. (e.g., +20 dBm for short-range, +30 dBm for long-range).

- Noise Figure (NF) (dB): A measure of how much noise the receiver adds to the signal. A lower NF indicates better receiver sensitivity, meaning it can detect weaker signals more effectively. Typical values range from 1 dB to 5 dB, with lower being better.

- Gain (dB): The amplification provided by the module. For Tx, it's the power gain from input to output; for Rx, it's the gain from antenna input to baseband output. Gain flatness across the frequency band is also important.

- Linearity (IP3/P1dB):

- Third-Order Intercept Point (IP3): A theoretical point where the power of desired signals equals the power of intermodulation products generated by non-linearity. Higher IP3 indicates better linearity and less distortion when multiple signals are present.

- 1 dB Compression Point (P1dB): The output power level at which the gain of the amplifier decreases by 1 dB from its ideal linear gain. It signifies the upper limit of the amplifier's linear operating range.

- Power Consumption (mW/W): The amount of electrical power the module consumes during operation. Crucial for battery-powered devices and overall system energy efficiency.

- Modulation Schemes Supported: The types of signal modulation (e.g., QPSK, QAM, OFDM) the module can encode/decode. This determines the data throughput and spectral efficiency.

- Dimensions and Weight: Physical size and mass, critical for compact and lightweight applications like drones or wearable devices.

- Operating Temperature Range (°C): The temperature extremes under which the module can reliably function. Important for industrial, automotive, and aerospace applications. (e.g., -40°C to +85°C).

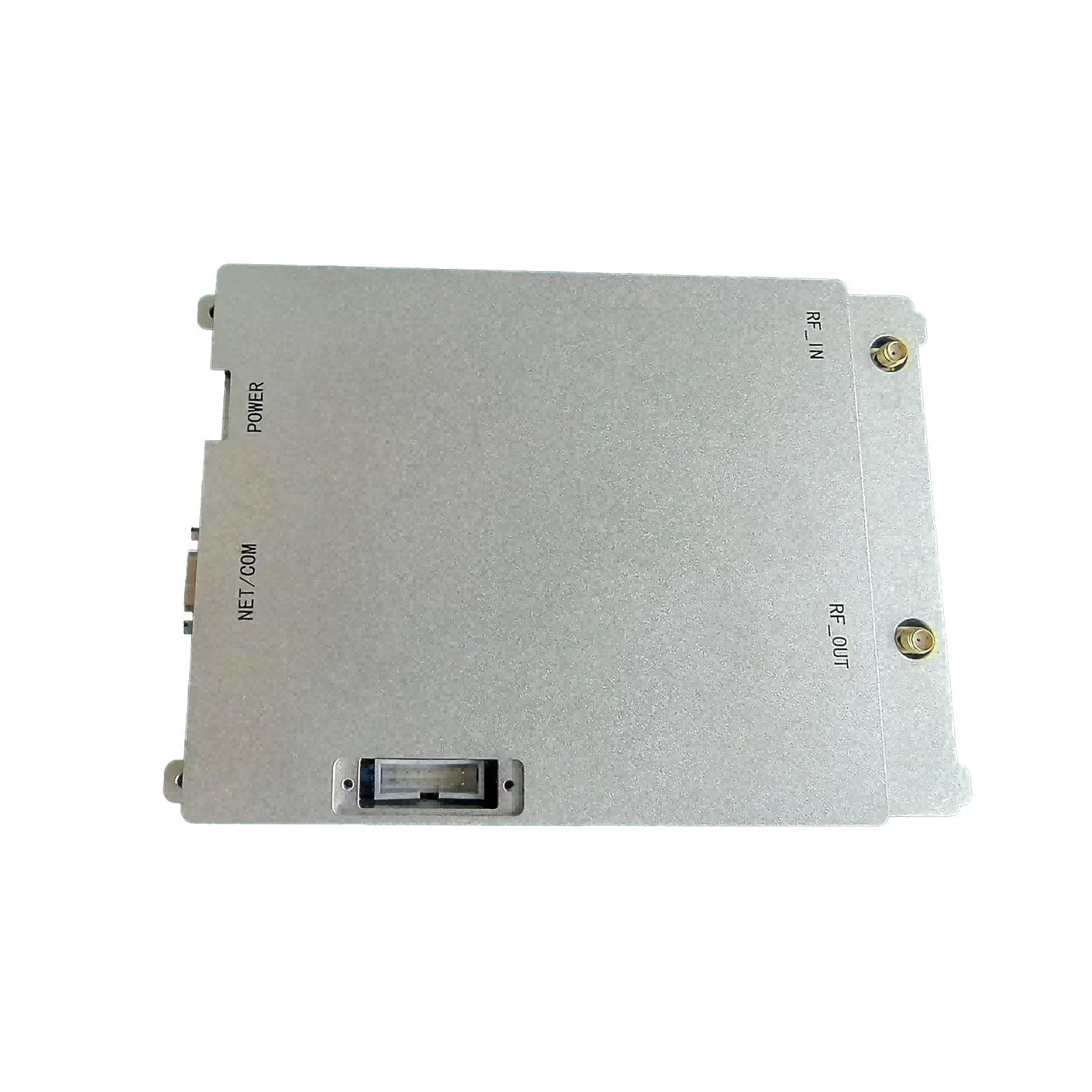

Figure 1: Internal components of a high-performance Tx/Rx Module, highlighting precision engineering.

Typical Tx/Rx Module Parameter Table

This table provides a general overview of common parameters found in various Tx/Rx Modules, demonstrating the range and diversity available in the market. Actual specifications will vary by specific product model and intended application.

| Parameter | Units | Typical Range (Consumer/IoT) | Typical Range (Industrial/High-Performance) | Significance |

|---|---|---|---|---|

| Frequency Range | GHz | 2.4 - 5.8 | 0.1 - 90+ (including mmWave) | Determines compatibility with communication standards. |

| Output Power (Tx) | dBm | +10 to +20 | +25 to +45 | Affects range and signal strength. |

| Receiver Sensitivity | dBm | -90 to -100 | -105 to -115 | Ability to detect weak signals. Lower (more negative) is better. |

| Noise Figure (Rx) | dB | 2.5 - 4.5 | 0.8 - 2.0 | Indicates noise added by the receiver. Lower is better. |

| Gain (Tx/Rx) | dB | 15 - 30 | 25 - 50+ | Signal amplification. |

| P1dB | dBm | +10 to +25 | +20 to +40+ | Output power limit before significant non-linearity. |

| IP3 | dBm | +20 to +35 | +35 to +50+ | Linearity under multi-tone conditions. Higher is better. |

| Supply Voltage | V | 1.8 - 5.0 | 3.3 - 12.0 | Operating voltage requirement. |

| Power Consumption | mW/W | 50 - 500 (active) | 1 - 10 (standby), 100 - 1000+ (active) | Energy efficiency. |

| Operating Temperature | °C | -20 to +70 | -55 to +125 | Environmental resilience. |

Diverse Application Scenarios of Tx/Rx Modules

The versatility of Tx/Rx Modules makes them indispensable across a multitude of industries. From enabling remote control to facilitating high-speed data transfer, their applications are vast and continue to expand:

- Drones and UAVs: Essential for reliable long-range command and control (C2) links, real-time video transmission, and telemetry data. High-performance Tx/Rx Modules ensure stable communication even in challenging urban or remote environments, critical for safe drone operation and mission success.

- Telecommunications (5G/6G & Satellite): Fundamental components in base stations, small cells, and user equipment (UE) for high-bandwidth, low-latency 5G/6G networks. In satellite communication, they enable uplink and downlink transmissions, facilitating global connectivity and data relay.

- Radar Systems: Used in automotive radar for ADAS (Advanced Driver-Assistance Systems), weather radar, and defense radar. They enable precise target detection, ranging, and velocity measurement by transmitting and receiving high-frequency pulses.

- Industrial IoT (IIoT): Facilitate wireless sensor networks for monitoring equipment, environmental conditions, and asset tracking in factories, smart grids, and infrastructure. Robust Tx/Rx Modules are crucial for reliable data acquisition in harsh industrial settings.

- Medical Devices: Enable wireless connectivity for patient monitoring systems, portable diagnostic tools, and robotic surgery. Low power consumption and high reliability are key requirements.

- Test & Measurement Equipment: Used in spectrum analyzers, signal generators, and network analyzers to characterize RF components and systems. High linearity and accuracy are paramount.

- Security and Surveillance: Power wireless cameras, motion sensors, and alarm systems, ensuring secure and dependable data transmission for monitoring critical areas.

Technical Advantages and Differentiators of Leading Tx/Rx Modules

The market for Tx/Rx Modules is highly competitive, with manufacturers striving to offer superior performance and unique advantages. Leading solutions distinguish themselves through:

- Advanced Semiconductor Technologies: Utilizing state-of-the-art materials like Gallium Nitride (GaN) for power amplifiers and Silicon-Germanium (SiGe) for low-noise amplifiers (LNAs). GaN offers high power density, efficiency, and robustness, making it ideal for high-power Tx applications. SiGe provides excellent noise performance and integration capabilities for Rx.

- Superior Signal Integrity: Meticulous design ensures minimal signal degradation, low phase noise, and excellent error vector magnitude (EVM) across the operational band. This translates to higher data rates and more reliable communication.

- High Integration and Compact Footprint: Leveraging System-in-Package (SiP) or Module-on-Chip (MoC) approaches to combine multiple RF front-end components (filters, switches, PAs, LNAs) into a single compact solution, simplifying PCB design and reducing overall system size.

- Broadband Performance: While some modules are optimized for narrow bands, leading Tx/Rx Modules offer broad frequency coverage, providing flexibility for multi-standard or future-proof applications.

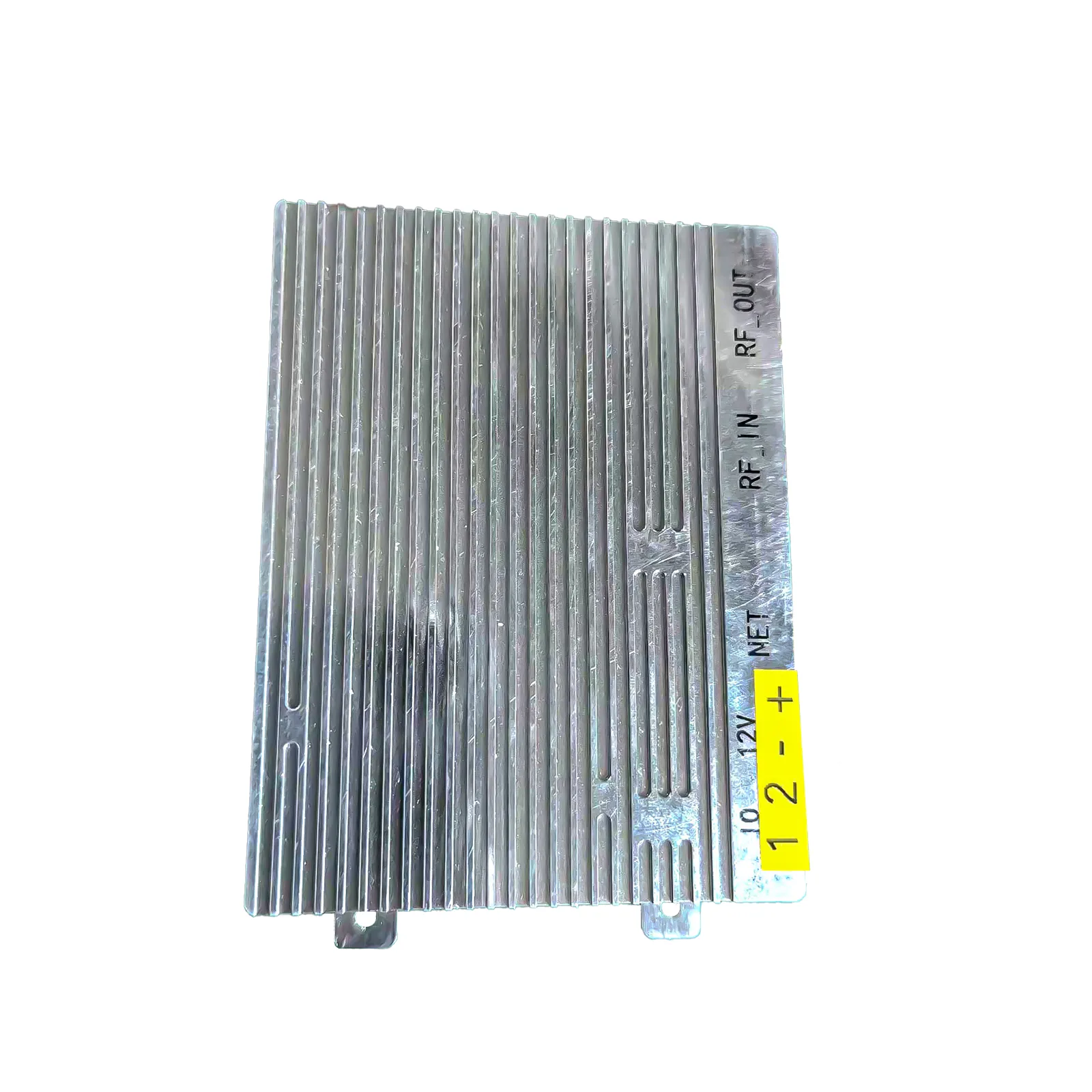

- Robust Thermal Management: Effective heat dissipation strategies (e.g., advanced packaging, heatsinks, thermal vias) ensure stable performance and extended lifespan, especially critical for high-power applications.

- Low Latency Operation: Optimized internal processing and interface designs minimize delays, crucial for real-time applications like drone control and autonomous driving.

- Energy Efficiency: Innovative power-saving modes, dynamic power management, and highly efficient amplifier designs significantly reduce overall power consumption, extending battery life in portable devices. For instance, an efficiently designed Tx/Rx Module can reduce power consumption by up to 30% compared to conventional designs, leading to substantial energy savings in large-scale deployments.

- Environmental Resilience: Designed to meet stringent industrial and military standards for vibration, shock, temperature extremes, and humidity, ensuring reliable operation in the most demanding environments. For instance, our modules are tested to operate continuously from -40°C to +85°C.

Figure 2: Illustrative application of a Tx/Rx Module in advanced drone communication systems.

Manufacturer Comparison: Selecting Your Ideal Tx/Rx Module Partner

Choosing the right manufacturer for your Tx/Rx Module needs is as crucial as selecting the module itself. Different manufacturers specialize in various aspects, from high-volume consumer-grade solutions to ultra-performance, specialized modules for defense or space applications. When evaluating partners, consider the following:

| Criteria | Manufacturer A (General Purpose/High Volume) | Manufacturer B (Specialized/High Performance) | Our Company (Balanced & Customizable) |

|---|---|---|---|

| Primary Focus | Cost-effective, mass-market IoT/Consumer Electronics | Ultra-low noise, high linearity, defense/space applications | High-reliability, balanced performance for Industrial & Drone applications |

| Product Range | Standard Wi-Fi/Bluetooth, basic cellular modules | High-frequency mmWave, specialized RFICs, custom ASICs | Broadband RF modules, custom frequency ranges, integrated solutions for drone systems |

| Key Advantage | Price point, large production capacity | Absolute performance, leading-edge technology (e.g., GaN HEMT processes) | Robustness, customizability, excellent support, proven reliability in drone communication. Our Tx/Rx Modules typically exhibit a Mean Time Between Failures (MTBF) exceeding 150,000 hours. |

| Certifications | ISO 9001, CE, FCC (basic) | ISO 9001, AS9100 (Aerospace), MIL-STD compliant | ISO 9001:2015, RoHS Compliant, IPC-A-610 Class 2/3, CE, FCC. We have been serving the industry for over 10 years. |

| Customization | Limited (firmware tweaks) | Extensive (full chip design) | Moderate to High (frequency tuning, power levels, interface adaptations, custom packaging) |

| Target Industries | Smart Home, Consumer Wearables | Aerospace & Defense, High-End Telecom | Drones & UAVs, Industrial IoT, Robotics, Advanced Surveillance |

Our company stands out by offering a unique blend of high performance, customizable solutions, and unparalleled reliability, specifically tailored for demanding applications like professional drone systems. Our Tx/Rx Modules are not just components; they are engineered solutions designed to seamlessly integrate into your critical systems, ensuring optimal performance and longevity. We pride ourselves on our deep understanding of the unique challenges faced by industries such as drone communication, petrochemical, metallurgy, and water treatment, enabling us to deliver solutions that excel in energy efficiency and anti-corrosion properties where applicable.

Crafting Perfection: The Manufacturing Process of a High-Performance Tx/Rx Module

The creation of a reliable and high-performance Tx/Rx Module involves a meticulous multi-stage manufacturing process, combining advanced materials with precision engineering. Here's a detailed look at the typical workflow, designed to ensure superior quality and long-term durability:

Tx/Rx Module Manufacturing Process Flow

Initial design phase using advanced CAD (Computer-Aided Design) and electromagnetic simulation software (e.g., Keysight ADS, Ansys HFSS). This step optimizes RF performance (impedance matching, gain, linearity) and thermal management. Material selection, such as high-frequency laminates (e.g., Rogers Corporation's RO4000 series, Arlon substrates) or low-temperature co-fired ceramic (LTCC) for compact, high-integration modules, is finalized here based on target frequency and power.

Manufacturing of the module's base substrate. For PCB-based modules, this involves multi-layer PCB fabrication with precise trace etching. For ceramic modules, it includes ceramic powder pressing, green tape lamination, and co-firing processes. Our PCBs utilize a specialized blend of PTFE and ceramic fillers for enhanced thermal stability and low loss characteristics at high frequencies.

High-precision automated assembly. This includes Surface Mount Technology (SMT) for passive components (resistors, capacitors) and active components (ICs, transistors). For bare die components (e.g., GaAs or GaN MMICs), advanced processes like die attach (epoxy or solder paste) and wire bonding (gold or aluminum wires for electrical connections) are employed to ensure minimal signal loss and maximum reliability.

The assembled module is encased in a protective package. This can range from plastic encapsulation for cost-effective solutions to hermetic sealing in metal (e.g., aluminum, Kovar) or ceramic packages for high-reliability, harsh-environment applications. Precision CNC machining is used for custom metal enclosures, ensuring perfect fit and optimal thermal dissipation. For instance, our robust aluminum housings are precision CNC-machined from aerospace-grade alloys for exceptional durability and EMI shielding.

Rigorous multi-stage testing is paramount. Each Tx/Rx Module undergoes comprehensive RF performance testing (e.g., S-parameter measurements, output power, noise figure, linearity tests using vector network analyzers and spectrum analyzers). Environmental testing includes temperature cycling, humidity exposure, and vibration/shock tests (e.g., MIL-STD-810G). Reliability tests like accelerated life testing are conducted to project an extensive usage lifespan. All modules adhere to stringent industry standards like ISO 9001 and ANSI for quality control, with a typical operating lifespan exceeding 10 years, even in challenging environments like petrochemical and metallurgical plants where corrosion and extreme temperatures are prevalent.

Final visual inspection, cleaning, and packaging. Comprehensive quality control checks are performed to ensure every module meets our stringent specifications and passes all final functional tests before shipment. Traceability systems log every step of the manufacturing process.

Our commitment to excellence ensures that every Tx/Rx Module delivered meets the highest standards of reliability and performance. This meticulous process is what allows our products to excel in challenging sectors such as petrochemical, metallurgy, and water supply/drainage, where features like anti-corrosion materials and robust sealing are critical. For example, the specialized coatings applied to our modules in these environments provide superior resistance to corrosive agents, significantly extending their operational lifespan and reducing maintenance costs, thereby delivering significant long-term energy savings.

Figure 3: Advanced testing procedures ensuring the quality and reliability of Tx/Rx Modules.

Custom Solutions and Partnership Opportunities

Recognizing that off-the-shelf solutions may not always perfectly align with unique project requirements, we offer extensive customization services for our Tx/Rx Modules. Our engineering team collaborates closely with clients to develop tailor-made solutions, adapting parameters such as:

- Frequency Band Optimization: Tuning the module to specific, non-standard frequency ranges for specialized applications.

- Power Output Levels: Adjusting transmit power to meet specific range or regulatory requirements.

- Interface and Connectivity: Customizing connectors, control interfaces (e.g., SPI, I2C, UART), and mechanical mounting options.

- Environmental Hardening: Enhancing protection against extreme temperatures, humidity, vibration, and EMI for mission-critical deployments in industries like oil & gas, defense, or aerospace. This includes specialized anti-corrosion treatments for our Tx/Rx Modules used in chemical processing or marine environments.

- Integration of Additional Functionality: Incorporating features like integrated power management units, specific filters, or specialized antenna interfaces within the module.

Our expertise extends beyond manufacturing; we act as a strategic partner, providing design consultancy, rapid prototyping, and comprehensive post-sales support. We have partnered with leading drone manufacturers and industrial automation companies globally, providing them with reliable and high-performance Tx/Rx Modules that are integral to their product's success. Our service duration in the industry spans over a decade, building a reputation for trustworthiness and exceptional customer satisfaction.

Real-World Impact: Application Cases of Tx/Rx Modules

The practical application of our Tx/Rx Modules showcases their reliability and performance in demanding scenarios:

- Case Study 1: Long-Range Inspection Drones for Pipelines (Petrochemical Industry)

A major petrochemical company utilized our custom Tx/Rx Modules in their fleet of inspection drones. The modules, hardened against corrosive atmospheres and extreme temperatures, provided a stable, encrypted 5.8 GHz communication link over 20 km. This enabled real-time, high-definition video feedback for detecting leaks and structural damage, significantly reducing manual inspection time and ensuring worker safety. The module's anti-corrosion properties ensured a lifespan far exceeding standard components in this harsh environment.

- Case Study 2: Autonomous Mining Vehicles (Metallurgy Industry)

In large-scale open-pit mines, autonomous hauling vehicles rely on ultra-reliable communication for navigation and safety protocols. Our Tx/Rx Modules, integrated into their communication backbone, offered robust connectivity in environments prone to heavy dust and electromagnetic interference from heavy machinery. Their low latency and high gain ensured continuous control and data exchange, crucial for preventing accidents and optimizing operations. The ruggedized design and long service life contributed to reduced downtime and maintenance costs.

- Case Study 3: Smart Water Management Systems (Water Supply & Drainage)

For a smart city initiative, our Tx/Rx Modules were deployed in remote water level sensors and automated valve control systems across a municipal water network. Operating on a secure, low-power frequency band, these modules facilitated continuous data collection on water flow, pressure, and leakage. Their energy efficiency (typically operating at less than 100mW average power) allowed for multi-year battery life in remote locations, minimizing manual intervention. The robust design resisted moisture and environmental degradation common in water treatment facilities, proving their long-term reliability and contributing to substantial energy savings by optimizing pump operations based on real-time data.

Ensuring Confidence: Trustworthiness and Support

Our commitment to client satisfaction extends far beyond the sale. We prioritize trustworthiness through transparency, robust support, and clear policies:

Frequently Asked Questions (FAQ)

Delivery Cycle & Quality Assurance

Our standardized production processes and robust supply chain management ensure efficient delivery. For standard products, typical lead times are 2-4 weeks. For custom Tx/Rx Modules, detailed project timelines are provided upfront, with regular updates. Every module undergoes 100% functional testing and batch-level reliability checks. We hold an ISO 9001:2015 certification, reflecting our unwavering commitment to quality management systems.

Comprehensive Warranty and Customer Support

We stand behind the quality of our Tx/Rx Modules with a comprehensive 3-year warranty against defects in materials and workmanship. Our dedicated customer support team and expert engineers are available to provide technical assistance, answer queries, and offer solutions, ensuring your long-term success with our products.

References and Further Reading

- IEEE Transactions on Microwave Theory and Techniques - A leading academic journal for advanced RF and microwave research, often featuring breakthroughs in Tx/Rx Module design and materials.

- Microwaves & RF - An industry publication offering insights into new products, design techniques, and market trends for RF and microwave components, including Tx/Rx Modules.

- Electronic Design - RF & Microwave Section - Provides articles and whitepapers on the latest developments in RF components, system integration, and test methodologies relevant to Tx/Rx Modules.

- GSMA: 5G Millimeter Wave Explained - Insights into the evolving landscape of 5G technologies and the role of high-frequency modules.

- Sensors (MDPI) Special Issue on UWB Wireless Sensor Networks - Academic perspectives on module applications in advanced sensor networks.

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 21 May 2025

-

09 March 2021 25 Dec 2024

-

09 March 2021 14 Oct 2022

-

09 March 2021 25 Dec 2024