RF Amplifier Transistors High Power & Efficiency RF Solutions

- Market Growth and Demand Patterns for RF Amplification Components

- Technical Advantages of Modern RF Power Amplifier Transistors

- Performance Comparison of Leading Semiconductor Manufacturers

- Design Considerations for Custom RF Amplifier Solutions

- Thermal Management Techniques for High-Power RF Transistors

- Real-World Application Case Studies Across Industries

- Future Development Pathways for RF Transistor Technology

(rf amplifier transistor)

The Critical Role of RF Amplifier Transistors in Modern Electronics

RF amplification components serve as foundational elements across wireless communication infrastructures where signal integrity dictates system performance. The global RF power amplifier transistor market is projected to reach $4.3 billion by 2028, growing at 11.2% CAGR according to recent industry analysis. This growth trajectory stems from escalating demand in 5G infrastructure deployment, with over 3.2 million new base stations requiring high-efficiency amplification solutions. Modern rf amplifier transistor

designs specifically address challenges like signal distortion in crowded frequency bands and thermal dissipation at higher power densities. Cutting-edge semiconductor materials including gallium nitride (GaN) and silicon carbide (SiC) now enable transistor operation beyond 100 MHz frequency ranges while maintaining stability under extreme environmental conditions.

Market Dynamics and Growth Projections

Telecommunications drives 68% of global RF transistor consumption, with automotive radar systems representing the fastest-growing segment at 19% annual increase. Component shortages during 2021-2022 highlighted supply chain vulnerabilities, causing lead times to extend from 12 weeks to 52 weeks for popular rf power amplifier transistor models. Inventory-to-sales ratios dropped to historic lows of 0.85 during this period, triggering redesign initiatives toward alternative component solutions. Defense applications account for approximately $900 million of annual RF transistor purchases, emphasizing the strategic importance of domestic semiconductor manufacturing capabilities. Emerging markets in Southeast Asia are establishing local production facilities, with Vietnam semiconductor exports increasing 127% since 2020.

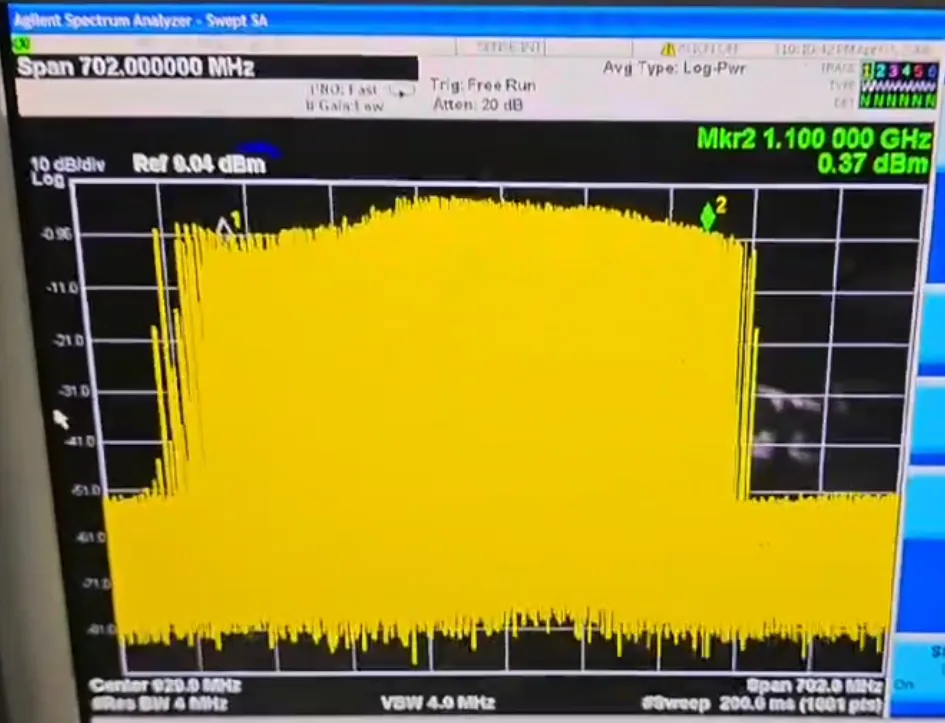

Technical Advantages of Modern RF Power Solutions

Advanced rf amplifier transistor designs now achieve peak power-added efficiency (PAE) exceeding 75% through novel circuit architectures like Doherty configurations. Temperature stability represents a critical improvement metric, with the latest devices maintaining ±0.1 dB gain variation across -40°C to +125°C operational ranges. Third-generation semiconductor materials demonstrate significant advantages:

Gallium nitride RF transistors achieve power densities of 8-10 W/mm compared to gallium arsenide's 1-2 W/mm, enabling 40% smaller footprint amplifiers. Linearity improvements reduce adjacent channel power ratio (ACPR) to -55 dBc through digital predistortion compatibility, crucial for 5G NR modulation schemes. Material developments allow operation at higher voltages (28V-50V systems versus traditional 12V designs), cutting current requirements and reducing energy consumption in high-power transmission scenarios.

Manufacturer Performance Comparison

| Model | Frequency Range | Output Power | PAE | Thermal Resistance | Package Type |

|---|---|---|---|---|---|

| MRF300 (NXP) | 1.8-400 MHz | 300 W | 72% | 0.35°C/W | Flange |

| BLF578XR (Ampleon) | 470-860 MHz | 200 W | 75% | 0.29°C/W | H2 |

| MRF1K50H (Microchip) | 5-500 MHz | 1700 W | 68% | 0.15°C/W | P1 |

| GHV-1C200 (Wolfspeed) | DC-2.5 GHz | 200 W | 65% | 1.2°C/W | CLL |

The MRF300 transistor exhibits exceptional performance in industrial heating and plasma generation applications due to its robust thermal characteristics and optimized input/output impedance matching. High-reliability packaging remains a key differentiator, with military-qualified devices featuring hermetic sealing exceeding 10,000 temperature cycles.

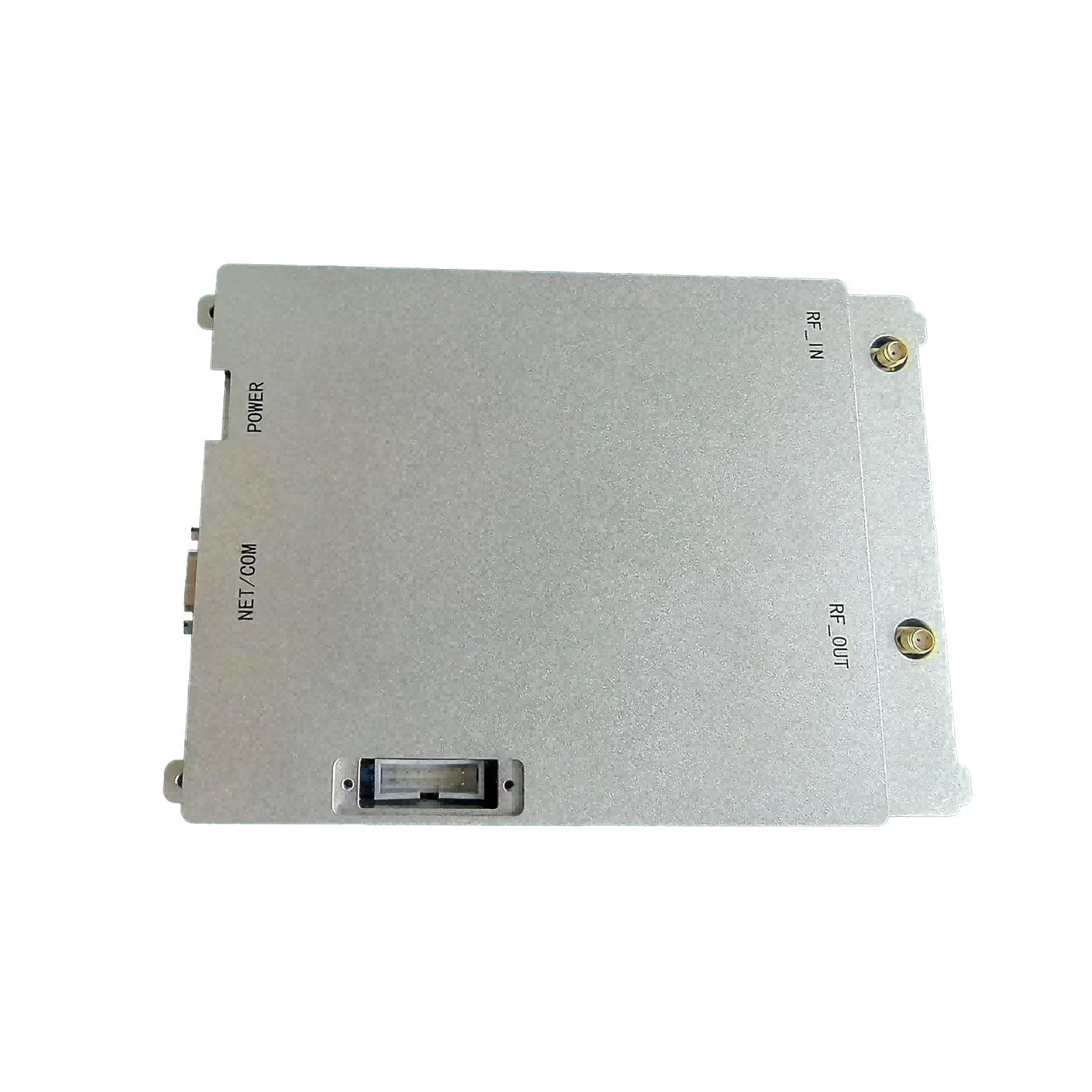

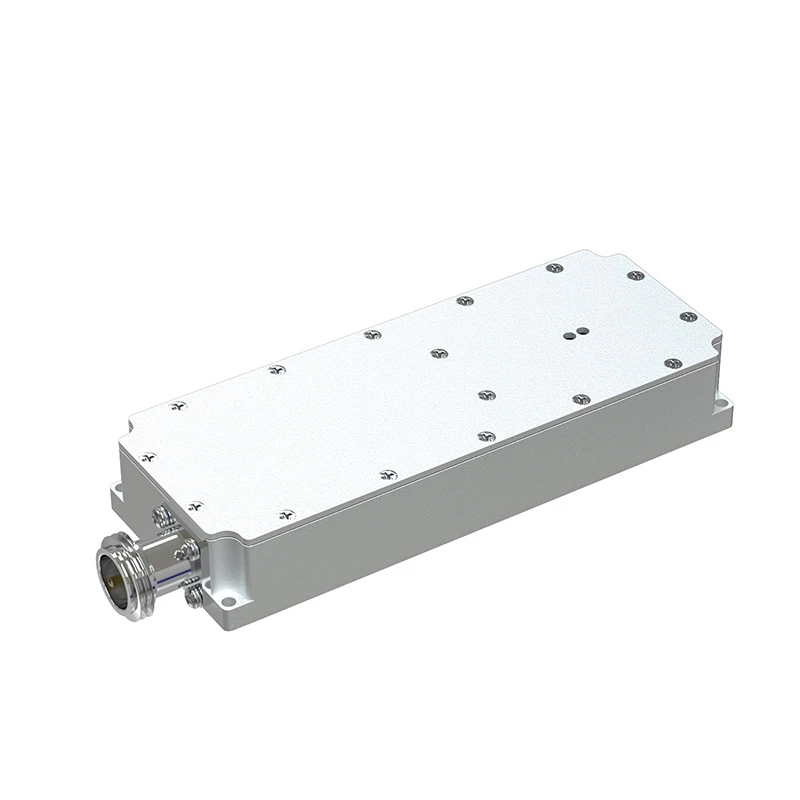

Custom Engineering Implementation Approaches

Industrial RF systems require customized configurations addressing specific operational challenges. Effective thermal dissipation represents the primary constraint in high-power amplifier design, influencing material selection:

Direct Bonded Copper (DBC) substrates provide thermal conductivity improvements exceeding 300 W/mK versus standard FR-4 PCB materials (0.25 W/mK). Phase-change thermal interface materials maintain mechanical stability across expansion cycles while achieving thermal resistances below 0.05 K-cm²/W. Application-specific optimization must consider harmonic termination circuits to minimize reflected power damage. Commercial broadcasting amplifiers implement notch filters at 2ⁿd and 3ʳᵈ harmonic frequencies while maintaining fundamental frequency VSWR below 1.5:1. Modern rf amplifier transistor designs now incorporate integrated temperature monitoring diodes and bias sequencing logic for comprehensive system protection.

Industrial Implementation Case Studies

Medical sterilization systems leverage RF power amplification operating at 13.56 MHz for efficient plasma generation. Implementation of GaN-based amplifier transistors reduced power consumption by 35% at 6 kW output levels while decreasing system dimensions by 45%. Semiconductor manufacturing applications require exacting frequency stability, with plasma etcher systems achieving ±0.01% frequency control through temperature compensated oscillator circuits. Broadcast infrastructure deployments demonstrated remarkable reliability metrics with MRF300 transistor-based transmitters accumulating 120,000 operational hours at FM radio stations without device replacement. Critical technical parameters included harmonic suppression exceeding 80 dBc and signal-to-noise ratios maintained above 60 dB across 20-year service life.

Future Development Trajectories for RF Transistor Technologies

Evolution of rf amplifier transistor technology centers on heterogeneous integration approaches combining silicon control circuitry with wide bandgap semiconductor materials. Packaging innovations address thermal management challenges through advanced methodologies:

Embedded cooling channels enable direct liquid cooling of rf power amplifier transistor dies, increasing power density limits by 3x without compromising reliability. Future military systems will integrate RF power amplification with beamforming architectures using gallium nitride monolithic microwave integrated circuits (GaN MMICs). Automotive radar systems at 77 GHz demand increasingly compact solutions with integrated antenna-amplifier modules entering production. Research indicates diamond semiconductor substrates could eventually increase power density beyond 20 W/mm at frequencies exceeding 100 GHz, representing fundamental advancement possibilities for rf amplifier transistor capabilities.

(rf amplifier transistor)

FAQS on rf amplifier transistor

What are the key applications of RF power amplifier transistors?

Q: What are the key applications of RF power amplifier transistors?

A: RF power amplifier transistors are used in wireless communication infrastructure like cellular base stations. They enable signal broadcasting in radar and satellite systems. Industrial RF heating and medical equipment also leverage their capabilities.

What makes the MRF300 transistor suitable for RF amplifiers?

Q: What makes the MRF300 transistor suitable for RF amplifiers?

A: The MRF300 offers high gain and efficiency at frequencies up to 500MHz. Its robust design handles 300W power outputs with excellent thermal stability. These traits make it ideal for broadcast and industrial RF systems.

How do RF amplifier transistors improve signal transmission?

Q: How do RF amplifier transistors improve signal transmission?

A: They boost weak RF signals while maintaining signal integrity. Minimized distortion ensures accurate data transfer. This enables reliable long-range wireless communications.

What factors determine RF amplifier transistor efficiency?

Q: What factors determine RF amplifier transistor efficiency?

A: Material technology like GaN or LDMOS impacts power conversion rates. Thermal management directly affects sustained performance. Circuit design and impedance matching also optimize efficiency.

Why choose MRF300 transistors over alternatives?

Q: Why choose MRF300 transistors over alternatives?

A: MRF300 provides superior thermal performance and ruggedness at high VHF/UHF bands. Broadband capability reduces circuit complexity. Higher reliability in demanding applications justifies potential cost premiums.

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 21 May 2025

-

09 March 2021 25 Dec 2024

-

09 March 2021 14 Oct 2022

-

09 March 2021 25 Dec 2024