Phased Array Radar: AESA Beam Steering, 3D Tracking

Phased Array Radar is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of radar and radio navigation equipment. This article explores how YiYuan ComTech Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Phased Array Radar Overview

- Benefits & Use Cases of Phased Array Radar in Manufacturing of radar and radio navigation equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Phased Array Radar from YiYuan ComTech Co., Ltd.

Phased Array Radar Overview

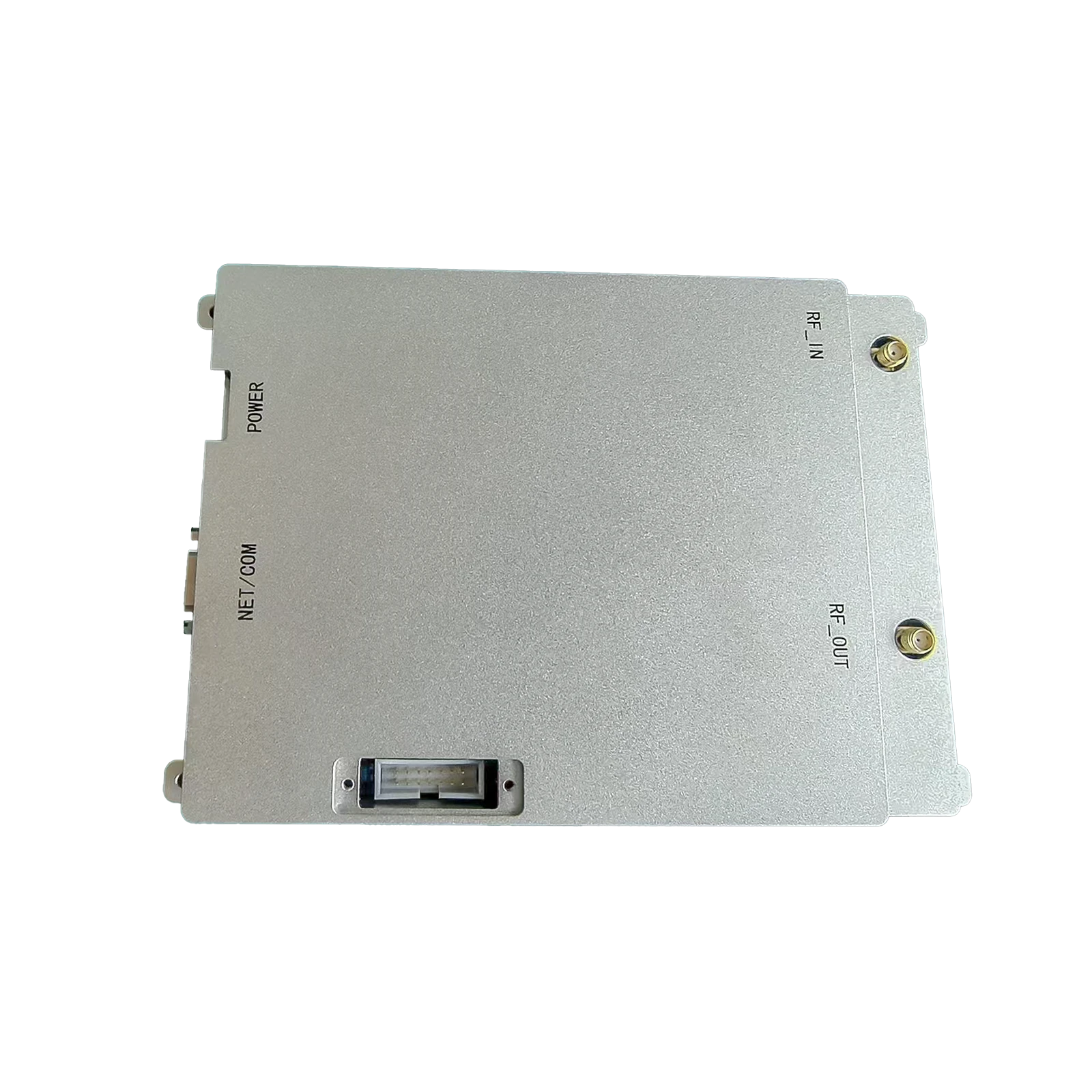

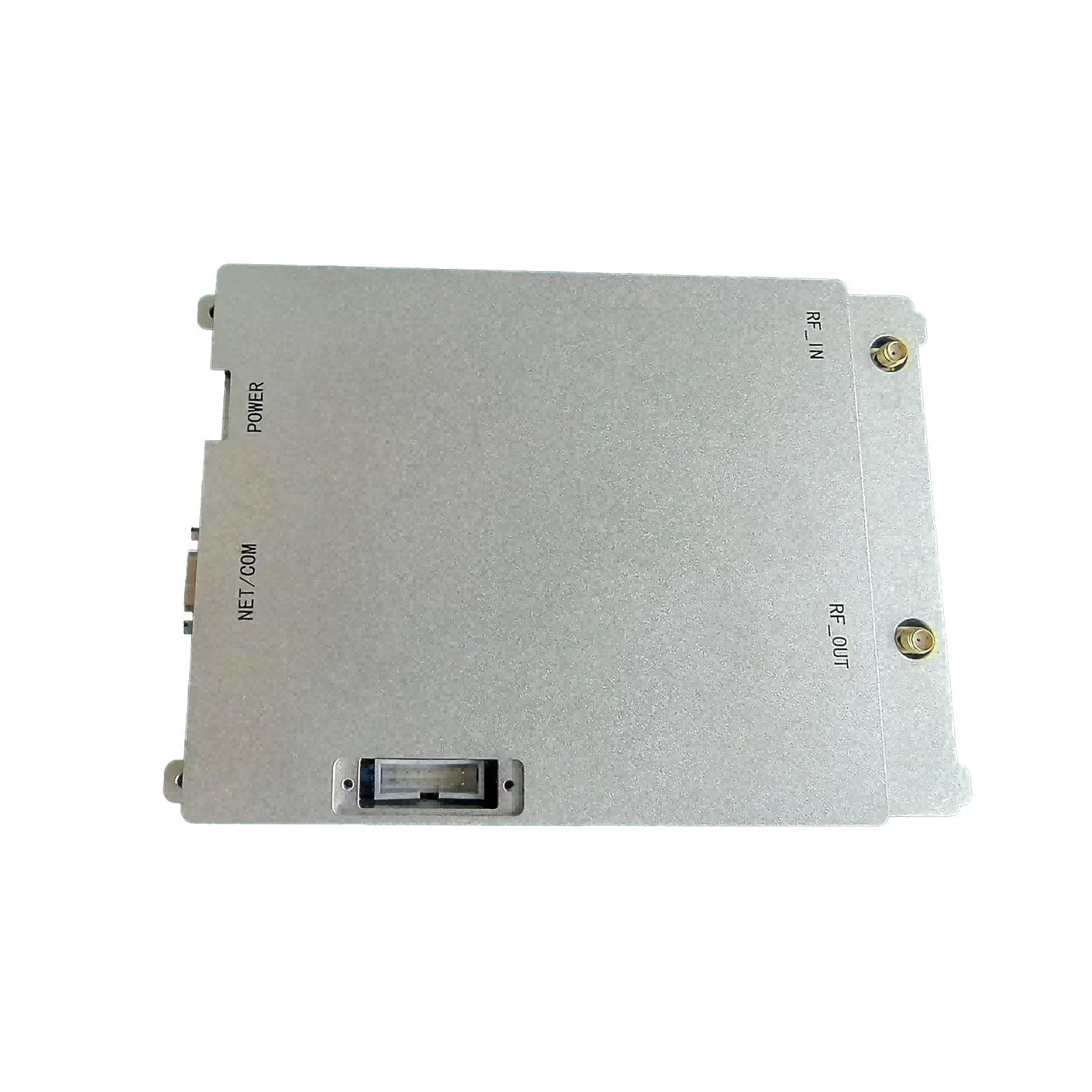

Phased Array Radar uses electronically steered antenna elements to form and steer beams without mechanical rotation, enabling rapid multi-target detection, tracking, and classification. For B2B decision makers in the Special Equipment Manufacturing Industry, this architecture delivers high reliability, compact form factors, and flexible deployment across land, sea, and air platforms. By leveraging active electronically scanned array (AESA) or passive phased array designs, these systems support dynamic beam scheduling, low sidelobe levels, and superior clutter suppression—critical for radar and radio navigation equipment manufacturing. YiYuan ComTech Co., Ltd. builds phased array systems with modular RF front-ends, scalable channel counts, and advanced signal processing pipelines. Typical specs include wideband operation, high update rates, and digital beamforming that enhances detection sensitivity and angular accuracy. In a recent integrator project, a compact array from YiYuan ComTech replaced a mechanical system, cutting scan latency by over 60% while improving target revisit rates for high-mobility scenarios. For OEMs and system integrators, YiYuan ComTech’s engineering depth shortens integration cycles and ensures consistent, verifiable performance from prototype to volume manufacturing.

Benefits & Use Cases of Phased Array Radar in Manufacturing of radar and radio navigation equipment

In radar and radio navigation equipment manufacturing, Phased Array Radar streamlines both product performance and lifecycle engineering. Common applications include perimeter surveillance, low-altitude monitoring, UAV detection and tracking, coastal security, navigation aids, and traffic management. Electronic beam steering supports adaptive scan patterns, while multi-beam operation enables simultaneous search and track—delivering higher situational awareness within the same time budget. Key advantages include fast reconfiguration, software-defined modes, graceful degradation (through element-level redundancy), and compact SWaP (size, weight, and power) profiles. YiYuan ComTech Co., Ltd. provides end-to-end support—from array design and RF front-end optimization to calibration, thermal management, and embedded algorithms—ensuring OEMs can differentiate on accuracy, range, and resilience. Compared with legacy mechanical radars, customers typically see faster target revisit rates, higher probability of detection in clutter, and easier on-platform integration due to fewer moving parts. For program managers, this means accelerated validation, smoother certification pathways, and better alignment to mission-specific requirements without costly, bespoke hardware redesigns.

Cost, Maintenance & User Experience

Total cost of ownership for Phased Array Radar benefits from reduced mechanical complexity and predictive maintenance. With fewer moving assemblies, downtime drops and MTBF improves, cutting spares and service visits. Digital calibration tools and remote diagnostics shorten maintenance windows, while modular line-replaceable units (LRUs) simplify field support. Over a multi-year horizon, customers report lower lifecycle cost per operational hour and faster ROI driven by improved uptime and mission performance. YiYuan ComTech Co., Ltd. emphasizes manufacturability, environmental robustness, and clear documentation—enabling smooth operator training and faster commissioning. Field feedback from Special Equipment Manufacturing Industry clients cites intuitive UI/UX, stable firmware updates, and consistent performance across temperature and EMI/EMC conditions. For procurement teams, predictable logistics, long-term component availability, and comprehensive after-sales support reduce program risk. Whether retrofitting an existing system or architecting a new platform, YiYuan ComTech’s phased arrays translate into measurable gains: shorter integration schedules, fewer unplanned interruptions, and better data fidelity for downstream C2 and analytics systems.

Sustainability & Market Trends in manufacturing

Manufacturers are aligning with stricter environmental standards, supply-chain transparency, and energy-efficient designs. Phased Array Radar supports this shift through solid-state architectures that consume less power for equivalent coverage, reduce mechanical waste, and extend service life. Trends shaping the market include software-defined radar modes, AI-assisted signal processing, edge fusion with EO/IR and AIS/ADS-B, and open systems architectures for interoperability. Regulatory emphasis on spectrum efficiency and electromagnetic compatibility further favors arrays with adaptive waveforms and low sidelobes. YiYuan ComTech Co., Ltd. invests in eco-conscious manufacturing practices, component longevity planning, and recyclable packaging. By prioritizing RoHS-compliant components, robust thermal design, and firmware-driven performance upgrades, YiYuan ComTech helps reduce e-waste and supports continuous improvement without hardware overhauls. For B2B decision makers, partnering with a forward-looking supplier de-risks programs against evolving standards and ensures technology roadmaps can accommodate future modes, band options, and data interfaces without costly redesigns.

Conclusion on Phased Array Radar from YiYuan ComTech Co., Ltd.

For the Special Equipment Manufacturing Industry—especially in the Manufacturing of radar and radio navigation equipment—Phased Array Radar delivers faster scanning, higher reliability, and software-driven adaptability. YiYuan ComTech Co., Ltd. combines engineering expertise with scalable manufacturing to help OEMs and integrators accelerate time-to-market and maximize lifecycle value. Ready to upgrade performance and reduce TCO? Contact us: email: joychengyy@gmail.com — Visit our website: https://www.drone-system.com

-

09 March 2021 24 Nov 2025

-

09 March 2021 24 Nov 2025

-

09 March 2021 24 Nov 2025

-

09 March 2021 23 Nov 2025

-

09 March 2021 23 Nov 2025

-

09 March 2021 21 May 2025

-

09 March 2021 25 Dec 2024

-

09 March 2021 14 Oct 2022

-

09 March 2021 25 Dec 2024