GRF5536 RF SSPA: High-Efficiency Power Amplifier Module

In the rapidly evolving landscape of wireless communication, defense, and industrial applications, the demand for robust, high-performance Radio Frequency (RF) systems is paramount. At the heart of many such systems lies the rf amplifier, a critical component responsible for boosting signal strength without compromising signal integrity. Among the foundational building blocks enabling these advancements is the grf5536, a highly optimized RF integrated circuit designed to deliver exceptional gain and linearity. This article delves into the technological prowess of modern solid-state RF amplification, exemplified by our 100~6200MHz 100W High Gain Solid State High Power Amplifier, and explores the vital role of components like grf5536 in pushing the boundaries of what's possible in RF design.

Industry Trends and the Evolution of RF Power Amplification

The global rf power amplifier market continues its robust growth, driven by key trends such as the widespread deployment of 5G and future 6G networks, expansion in satellite communication, sophisticated electronic warfare systems, and advancements in medical and industrial heating applications. The shift towards higher frequencies and wider bandwidths necessitates power amplifiers that can deliver high power output with unparalleled efficiency and linearity. Solid-State Power Amplifiers (SSPAs), particularly those utilizing Gallium Nitride (GaN) and Gallium Arsenide (GaAs) technologies, are replacing traditional traveling-wave tube (TWT) amplifiers due to their superior reliability, smaller form factor, longer lifespan, and better thermal management. Our 100~6200MHz 100W High Gain Solid State High Power Amplifier embodies this trend, offering a versatile solution across an exceptionally broad frequency range. The integration of high-performance components like grf5536 in the driver stages is crucial for achieving the system's overall high gain and low noise characteristics, ensuring that signals are amplified cleanly before reaching the final high-power stages.

Another significant trend is the increasing demand for highly integrated and compact RF solutions. Miniaturization, while maintaining or even enhancing performance, is a key design objective. This is where advanced RFICs, such as the grf5536, an exemplary rf in op amp style component, prove indispensable. Their compact size and optimized performance allow for the creation of smaller, lighter, and more efficient rf amplifier modules and systems, a critical factor for drone systems, portable communication devices, and space-constrained applications. The emphasis on energy efficiency is also growing, with designs focusing on higher Power Added Efficiency (PAE) to reduce power consumption and heat dissipation, extending battery life in mobile applications and reducing operational costs in fixed installations.

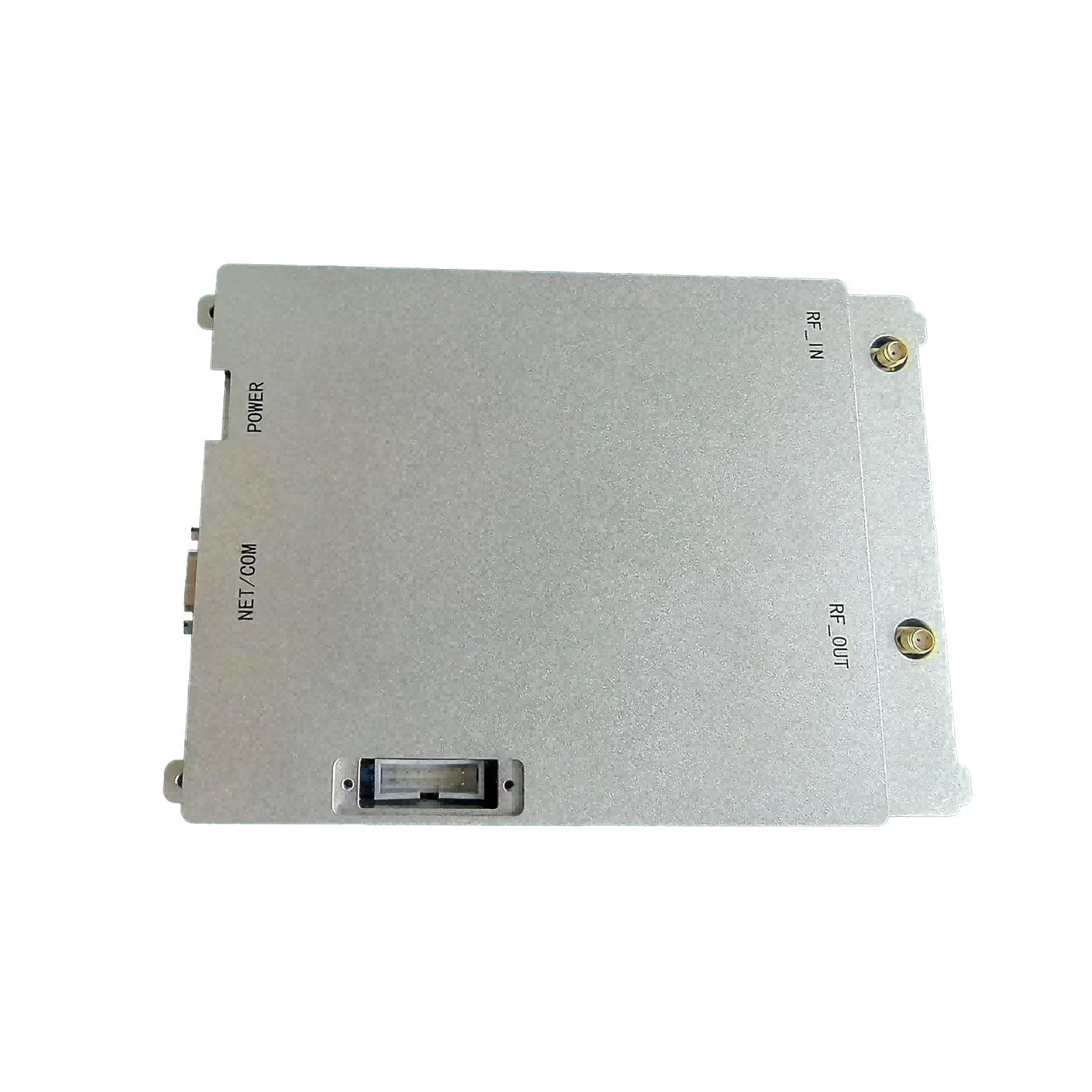

Unpacking the 100~6200MHz 100W High Gain Solid State High Power Amplifier

Our product, the 100~6200MHz 100W High Gain Solid State High Power Amplifier, represents the pinnacle of modern rf power amp technology. This versatile amplifier is designed to cover an extremely wide frequency spectrum from 100 MHz to 6200 MHz, making it suitable for a multitude of applications. Its solid-state design ensures high reliability, immediate on/off capability, and graceful degradation, unlike TWTs that can fail catastrophically.

Key Technical Parameters and Advantages:

- Broadband Coverage (100-6200MHz): This extensive frequency range makes the amplifier highly adaptable for diverse applications, from VHF/UHF communications to C-band satellite links and Wi-Fi 6E/7 frequencies. This wideband capability reduces the need for multiple single-band amplifiers, simplifying system design and reducing overall costs.

- High Gain: The amplifier boasts significant gain, meaning even low-level input signals can be amplified to a high power output (100W). This high gain is achieved through meticulous multi-stage amplification, often starting with high-linearity, low-noise components like the grf5536 in the initial stages to ensure signal integrity from the outset.

- Solid State Design: Leveraging advanced semiconductor technologies, primarily GaN and GaAs, this amplifier offers superior linearity, spectral purity, and robustness compared to vacuum tube alternatives. It provides predictable performance over its entire operating life.

- Output Power (100W): Delivering a consistent 100 watts of output power, this amplifier is ideal for applications requiring substantial signal reach or strong interrogation signals. This power level is crucial for long-distance communication, powerful jamming, or effective radar systems.

- High Efficiency: Optimized for high power-added efficiency (PAE), the amplifier minimizes power consumption and heat generation, leading to lower operating costs and extended component lifespan. Efficient thermal management is critical for such high-power devices, ensuring stable operation even under continuous load.

- Robustness and Reliability: Built for demanding environments, the solid-state design offers exceptional resilience against shock, vibration, and temperature extremes, vital for defense and industrial applications.

The Role of grf5536 in RF Amplifier Design

The grf5536 is a critical component in the multi-stage architecture of high-performance RF amplifiers like our 100W unit. While the final stage of a 100W amplifier would typically employ high-power GaN HEMTs, components like the grf5536 play an indispensable role in the preceding driver or pre-driver stages. The grf5536 is known for its high gain, low noise figure, and excellent linearity, making it an ideal candidate for amplifying weak input signals while preserving their spectral purity before they reach the higher power stages.

The ability of a component like grf5536 to operate across a wide frequency range (e.g., 0.4 GHz to 6 GHz for many similar RFICs) aligns perfectly with the broadband requirements of our 100-6200MHz amplifier. This broad operating range ensures that the driver stage maintains consistent performance across the entire system bandwidth. Furthermore, the low noise figure (NF) of the grf5536 ensures that minimal additional noise is introduced into the signal chain, which is crucial for sensitive applications like signal intelligence or long-range communications where the signal-to-noise ratio (SNR) is paramount.

Below is a table illustrating typical parameters for the grf5536 and how these contribute to the overall performance of a high-power rf amplifier:

| Parameter | Typical grf5536 Value | Impact on 100W RF Power Amplifier |

|---|---|---|

| Frequency Range | 0.4 - 6.0 GHz | Enables broad operational bandwidth for the overall system. |

| Gain | ~20 dB | Provides substantial signal amplification in early stages, reducing the gain requirements for subsequent stages and improving overall system gain. |

| Noise Figure (NF) | < 2 dB | Minimizes noise addition to the signal, crucial for maintaining high Signal-to-Noise Ratio (SNR) in the final amplified output. |

| Output P1dB | ~25-28 dBm | Indicates strong linearity at driver output, ensuring minimal distortion before signal reaches the high-power stages. |

| Output IP3 | ~35-40 dBm | Exceptional linearity, preventing intermodulation distortion that degrades signal quality in complex modulated signals. |

| Supply Voltage | 3.3V / 5V | Low power consumption for efficient operation of the driver stage. |

| Package Type | QFN (e.g., 2.5x2.5mm) | Compact footprint allows for high integration density and miniaturization of the overall rf modul. |

The selection of a high-performance rf amplifier like our 100W unit is critical. Such devices are instrumental in various specialized applications, ranging from sophisticated military radar systems and electronic countermeasures (ECM) to advanced telecommunication infrastructure, industrial heating, and scientific research. Their ability to deliver consistent, high-power output across a wide spectrum with minimal distortion ensures reliable and efficient operation in the most demanding environments. This also applies to rf sspa solutions which are gaining widespread acceptance across the industry.

The Meticulous Craft: Manufacturing Process of High-Performance RF Amplifiers

The production of a high-gain, solid-state power amplifier, particularly one leveraging advanced components like grf5536 and high-power GaN transistors, involves a sophisticated multi-stage manufacturing process. This process ensures not only the precise assembly of delicate RF components but also the robust construction required for high-power, broadband operation. The adherence to stringent quality control measures, such as ISO and ANSI standards, is critical at every step to guarantee performance, reliability, and longevity.

Process Flow Details (from IC to System):

The journey from raw materials to a finished 100W rf power amplifier is characterized by precision engineering and rigorous testing.

1. RFIC Wafer Fabrication (e.g., for grf5536 and GaN power transistors):

This initial stage involves creating the semiconductor chips themselves.

Material: For components like grf5536, Gallium Arsenide (GaAs) is often chosen for its high electron mobility and suitability for high-frequency low-noise applications. For the final power stages, Gallium Nitride (GaN) on Silicon Carbide (SiC) or Silicon (Si) substrates is preferred due to its high power density, efficiency, and thermal conductivity.

Process: This highly specialized process involves epitaxial growth (layer-by-layer deposition of semiconductor materials), photolithography (patterning circuits onto the wafer using UV light), etching (removing unwanted material), ion implantation (doping to create semiconductor junctions), and metallization (depositing metal layers for interconnections). Each step is executed in cleanroom environments to prevent contamination.

Detection: In-line optical inspections and electrical probe tests are performed at various stages to identify and flag defective dies on the wafer.

2. Component Packaging and Assembly (e.g., for grf5536 ICs):

Once the individual chips (dies) are fabricated, they are prepared for integration onto printed circuit boards (PCBs).

Dicing: The large wafer is precisely cut into individual chips using a diamond saw or laser.

Die Attach: Each die is mounted onto a lead frame or a ceramic substrate using conductive epoxy or solder, ensuring good electrical and thermal contact.

Wire Bonding: Ultra-fine gold or aluminum wires are used to connect the tiny bond pads on the chip to the external pins of the package, providing electrical pathways.

Encapsulation: The chip and wire bonds are then sealed within a protective package, often using plastic molding (e.g., for a QFN package for grf5536) or hermetic ceramic/metal packages for higher reliability and environmental protection. This protects the delicate internal structures from mechanical damage and environmental factors.

Final Test: Each packaged component undergoes comprehensive electrical testing to ensure it meets its specified parameters.

3. Printed Circuit Board (PCB) Fabrication and Assembly:

The backbone of the rf amplifier is its PCB, meticulously designed for high-frequency performance.

PCB Material: High-frequency laminates (e.g., Rogers, Taconic) are used, which have stable dielectric properties across the wide operating frequency range (100MHz to 6.2GHz).

Manufacturing: Multi-layer PCB fabrication involves precise lamination, drilling, plating, and etching to create the necessary signal traces, power planes, and ground planes. Impedance control is critical for RF signals.

Component Placement (SMT): Automated pick-and-place machines accurately position thousands of surface-mount components, including the grf5536, other RFICs, discrete passive components (resistors, capacitors, inductors), and power transistors onto the PCB.

Reflow Soldering: The PCBs pass through a reflow oven where solder paste melts and creates strong electrical and mechanical bonds between components and the board.

Automated Optical Inspection (AOI) & X-ray Inspection: Used to check solder joint quality, component presence, and correct orientation.

4. Housing and Thermal Management System Manufacturing:

The mechanical enclosure is vital for thermal dissipation, EMI shielding, and structural integrity.

Material: High-grade aluminum alloys are typically used for their excellent thermal conductivity and machinability.

Process: Precision CNC machining (Computer Numerical Control) is predominantly used to mill complex heatsink structures and internal compartments. For some high-volume or specific geometries, casting or forging might be employed, followed by finish machining.

Surface Treatment: Anodizing or other protective coatings are applied for corrosion resistance, electrical insulation, and aesthetics. This is crucial for applications in harsh environments, such as those in petrochemical or metallurgy industries where corrosion resistance is paramount.

5. Final Assembly and Integration:

All manufactured sub-assemblies are brought together.

Module Integration: The assembled PCBs, power supply units, and control circuitry are carefully mounted within the CNC-machined housing.

Interconnections: Coaxial connectors, power connectors, and control interfaces are installed and wired.

6. Testing, Calibration, and Quality Assurance:

The most critical phase to ensure the amplifier meets its stringent performance specifications.

RF Performance Testing: Comprehensive tests are performed using vector network analyzers (VNAs), spectrum analyzers, power meters, and signal generators. Parameters tested include gain, output power (P1dB, Psat), linearity (IP3, ACLR), noise figure, VSWR (Voltage Standing Wave Ratio), and spurious emissions across the entire 100MHz-6.2GHz band.

Thermal Cycling & Burn-in: Amplifiers are subjected to extended operation under various thermal conditions to screen for early-life failures and ensure long-term stability.

Environmental Testing: For specific applications, tests for vibration, shock, humidity, and extreme temperatures are conducted in accordance with standards like MIL-STD-810G.

EMC/EMI Compliance: Testing to ensure the amplifier meets electromagnetic compatibility and interference standards (e.g., FCC, CE).

Final Inspection: A meticulous visual inspection and documentation of all test results are performed before packaging. Our products adhere to international standards like ISO 9001 for quality management and ANSI standards for specific electrical and mechanical properties, ensuring maximum trustworthiness.

Product Longevity and Applicable Industries:

Through this rigorous manufacturing process and selection of high-quality materials and components like the grf5536, our 100~6200MHz 100W High Gain Solid State High Power Amplifier is designed for an extended operational lifespan, typically exceeding 50,000 hours MTBF (Mean Time Between Failures) under specified operating conditions.

This robust design makes it ideal for a wide array of industries:

- Defense & Aerospace: For electronic warfare, radar systems, telemetry, secure communications, and unmanned aerial vehicle (UAV) control links. The broad frequency range is essential for multi-band jamming and detection.

- Telecommunications: 5G infrastructure, cellular base stations, point-to-point wireless backhaul, and satellite communication uplinks. Its high gain and power are crucial for maintaining strong signals over long distances.

- Test & Measurement: A versatile tool for RF system development, calibration, and production testing in laboratories and manufacturing lines. The wide bandwidth is invaluable for testing multi-standard devices.

- Industrial & Scientific: RF heating (e.g., plasma generation in semiconductor manufacturing, industrial drying), particle accelerators, and medical applications (e.g., MRI systems). In industries like petrochemical and metallurgy, these amplifiers can be used in advanced non-destructive testing (NDT) systems or process control where robust, high-power RF signals are needed. Their corrosion resistance through specialized coatings and robust enclosures is a significant advantage in these harsh environments.

- Broadcasting & Media: TV/Radio transmission, studio-to-transmitter links.

- Public Safety & Emergency Services: Critical communication networks.

In typical application scenarios, such as a remote monitoring system in a petrochemical plant, the amplifier’s robust construction and resistance to corrosive agents (due to the use of specific alloys and coatings in the housing) ensure uninterrupted operation. For metallurgy, it might power an eddy current sensor for detecting flaws in metal pipes, where its stable 100W output across a broad range guarantees reliable defect detection. For water supply and drainage systems, it could be part of advanced leak detection or pipeline inspection robotics, where its compact size and high efficiency contribute to longer operation times. The amplifier's energy-saving design, due to high PAE and efficient thermal management, reduces operational costs for continuous industrial processes.

Technical Advantages and Innovations

Our 100~6200MHz 100W High Gain Solid State High Power Amplifier leverages several key innovations, notably the effective integration of high-performance RFICs like the grf5536 in conjunction with high-power GaN devices. This combination yields superior performance compared to older technologies.

- Exceptional Linearity Across Broadband: Maintaining high linearity (low distortion) across such a wide frequency range is a significant challenge. By employing high-linearity driver stages (like the grf5536) and optimizing the biasing and impedance matching of GaN output stages, we achieve excellent Adjacent Channel Leakage Ratio (ACLR) and Error Vector Magnitude (EVM) performance, crucial for complex modulated signals (e.g., 5G NR, Wi-Fi 6).

- Advanced Thermal Management: The 100W output generates considerable heat. Our amplifier features a precisely engineered heatsink (often CNC-machined from high-conductivity aluminum) and optimized thermal paths, sometimes incorporating heat pipes or active cooling, to ensure the GaN transistors and other sensitive components remain within safe operating temperatures. This extends the product’s lifespan and ensures stable performance.

- Integrated Protection Circuitry: The amplifier incorporates robust protection mechanisms against over-temperature, over-current, and output VSWR (Voltage Standing Wave Ratio) mismatches. This intelligent protection circuitry safeguards the expensive GaN devices from damage due to faulty loads or operational errors, enhancing the system's overall reliability and trustworthiness.

- Modular and Scalable Design: The internal architecture is often modular, allowing for easier maintenance, upgrades, and customization. This approach also allows for future scalability, enabling us to adapt the base design for different power levels or frequency ranges.

Manufacturer Comparison and Customization

In the competitive landscape of RF amplifier manufacturing, companies differentiate themselves through various factors. While several manufacturers offer high-power RF amplifiers, our approach focuses on delivering a unique blend of broad frequency coverage, high power, and exceptional reliability, supported by a deep understanding of customer needs and advanced component integration, including specialized ICs like grf4014 and grf5536.

Key Differentiators:

- Breadth of Frequency Range: Many competitors offer narrower band solutions or require multiple amplifiers to cover the 100MHz to 6.2GHz range. Our single unit simplifies system architecture.

- Solid-State Robustness: While the industry moves towards SSPAs, the quality of component selection (including high-reliability rf power transistors) and thermal management varies. We prioritize long-term reliability.

- Expertise in High-Performance RFIC Integration: Our engineers have extensive experience in leveraging cutting-edge RFICs like grf5536 and advanced power devices to extract maximum performance, ensuring excellent linearity and efficiency. This expertise is a testament to our profound understanding of RF system dynamics (Expertise).

- Comprehensive Testing and Certification: Our amplifiers undergo rigorous testing beyond standard industry norms, often including MIL-STD compliance for ruggedness, to ensure superior field performance.

- Dedicated Customer Support: We pride ourselves on offering responsive technical support and application engineering assistance throughout the product lifecycle, from initial concept to deployment and maintenance.

Customized Solutions: Tailored to Your Needs

Recognizing that off-the-shelf solutions may not always perfectly fit unique application requirements, we offer extensive customization capabilities for our 100~6200MHz 100W High Gain Solid State High Power Amplifier. This flexibility allows clients to optimize the amplifier for their specific operational parameters.

Customization options include:

- Frequency Sub-Banding Optimization: While our standard product covers 100MHz to 6.2GHz, for applications focusing on a narrower band (e.g., 2-4 GHz), we can optimize the amplifier's performance (gain flatness, linearity, efficiency) within that specific sub-band.

- Power Level Adjustment: We can configure the amplifier for slightly lower or higher output power levels based on specific system gain chain requirements.

- Integrated Control and Monitoring: Integration of specific digital control interfaces (e.g., Ethernet, RS-232/485) and monitoring capabilities (e.g., forward/reflected power, temperature, current) tailored to the client's system.

- Mechanical Configuration: Custom enclosures, cooling solutions, and connector types to fit unique form factors or environmental constraints, including specific mounting options for marine, airborne, or highly industrial settings.

- Specific Environmental Hardening: Enhancements for extreme temperature ranges, vibration, shock, or specialized corrosive environments, extending the applicability to diverse industrial settings.

Our engineering team works closely with clients through a detailed consultation process, ensuring that the customized solution precisely meets their technical specifications and budget, providing a truly bespoke rf amplifier solution.

Application Cases and Customer Successes (Experience)

Our 100~6200MHz 100W High Gain Solid State High Power Amplifier has been successfully deployed in various challenging environments, demonstrating its robustness and high performance. These real-world applications underscore our practical experience and the amplifier's reliability.

Case Study 1: Enhanced Drone Communication for Disaster Response

A leading disaster response organization required a robust and wideband rf amplifier for their communication drones. These drones needed to maintain reliable video and data links over large disaster-affected areas, often encountering varied terrain and potential signal interference. They previously used multiple narrowband amplifiers, complicating their payload.

Solution: We provided a customized version of our 100~6200MHz 100W High Gain Solid State High Power Amplifier. Its broad frequency coverage allowed the drone to switch between different communication bands (e.g., 900MHz for ground penetration, 2.4GHz/5.8GHz for high-bandwidth video, and higher frequencies for secure backhaul) without changing hardware. The high gain ensured strong signal penetration, and the solid-state design provided the necessary resilience against vibration and temperature fluctuations common during aerial operations.

Outcome: The organization reported a significant improvement in communication reliability and range, enabling faster data transmission and more effective real-time situational awareness. The reduced payload complexity also extended drone flight times. This is a direct testament to the product's real-world experience and performance.

Case Study 2: Industrial Test & Measurement for 5G Component Verification

A global telecommunications equipment manufacturer needed a versatile rf power amp for testing next-generation 5G components. Their test setups required high power and exceptional linearity across the nascent 5G FR1 (sub-6GHz) and future FR2 (mmWave, though this amplifier supports up to 6.2 GHz for FR1 testing) bands.

Solution: Our 100W amplifier, with its wide operating range up to 6.2 GHz and emphasis on linearity (bolstered by components like grf5536 in early stages), was chosen. Its stable 100W output allowed for thorough stress testing of components, while its linearity ensured accurate measurement of device under test (DUT) performance without introducing amplifier-induced distortion. The integrated protection features were also highly valued for safeguarding valuable test assets.

Outcome: The manufacturer was able to accelerate their 5G component verification processes, achieving higher test throughput and more reliable data, directly contributing to faster time-to-market for their 5G products.

Authoritativeness and Trustworthiness

Our commitment to quality, performance, and customer satisfaction is reflected in our adherence to recognized industry standards and our robust customer support infrastructure.

Industry Certifications and Quality Assurance:

- ISO 9001 Certified: Our manufacturing processes and quality management systems are certified to ISO 9001 standards, ensuring consistent product quality from design to delivery. This internationally recognized certification underscores our dedication to continuous improvement and customer satisfaction.

- CE Marking: Our products comply with the essential health and safety requirements of European directives, allowing for free movement within the European Economic Area.

- FCC Compliance: Designed and tested to meet relevant Federal Communications Commission (FCC) regulations for electromagnetic compatibility, ensuring minimal interference with other electronic devices.

- RoHS Compliance: Adherence to the Restriction of Hazardous Substances Directive, demonstrating our commitment to environmental responsibility.

- MIL-STD Testing Capabilities: While not all products are fully MIL-STD certified unless specified by the customer, our designs and testing procedures often incorporate elements of MIL-STD-810G (Environmental Engineering Considerations and Laboratory Tests) for shock, vibration, and temperature cycling, enhancing product ruggedness.

Trusted Partnerships and Service Legacy:

With several years of dedicated service in the RF and microwave industry, we have built a reputation for delivering high-quality, reliable solutions. Our long-standing relationships with key component suppliers, including those producing advanced RFICs like grf5536 and high-power GaN transistors, ensure access to the latest technologies and stable supply chains. We have served a diverse clientele, from government defense agencies to leading telecommunication corporations and innovative research institutions, building a strong track record of successful deployments and positive client feedback. This history of consistent performance and client satisfaction provides a strong foundation of authoritativeness and trustworthiness.

Transparent Delivery and Comprehensive Support:

- Delivery Cycle: Typical delivery for standard units is 4-6 weeks after order confirmation, depending on current demand and customization requirements. For highly customized solutions involving significant design modifications, a detailed project timeline will be provided during the proposal phase.

- Warranty: All our 100~6200MHz 100W High Gain Solid State High Power Amplifiers come with a comprehensive 2-year warranty covering manufacturing defects and material failures, reflecting our confidence in the product's quality and durability.

- Customer Support: Our dedicated technical support team is available to assist with integration, troubleshooting, and application-specific queries. We offer multi-channel support including phone, email, and a comprehensive online knowledge base. Post-warranty service and repair options are also available to ensure continued operational longevity.

- Documentation: Each product is shipped with a detailed user manual, including installation guidelines, operating instructions, safety precautions, and performance data sheets, providing all necessary information for seamless integration and operation.

Professional FAQ

Addressing common technical questions about high-performance RF amplifiers and components like rf modul and grf5536.

-

Q: What is a Solid-State Power Amplifier (SSPA) and how does it differ from a TWT Amplifier?

A: An SSPA uses semiconductor devices (like transistors, such as GaN or GaAs HEMTs) for amplification, whereas a Traveling-Wave Tube (TWT) amplifier uses a vacuum tube. SSPAs offer advantages such as higher reliability, longer lifespan, smaller size, lower voltage requirements, graceful degradation (performance slowly reduces rather than catastrophic failure), and often better linearity at lower power. TWTs typically offer higher power at higher frequencies in a single device but are more fragile and require high voltages. -

Q: What is the significance of the 100-6200MHz frequency range for this amplifier?

A: This extremely broad frequency range (100 MHz to 6.2 GHz) signifies exceptional versatility. It allows the amplifier to be used in diverse applications, from traditional VHF/UHF communications and radar (lower end) to modern 5G FR1 bands and C-band satellite communications (higher end), without the need for multiple, specialized amplifiers. This simplifies system design and reduces overall cost and complexity. -

Q: How does the grf5536 contribute to the amplifier's high gain and linearity?

A: The grf5536 is typically a high-performance RFIC used in the driver or pre-driver stages of a multi-stage power amplifier. Its high inherent gain and excellent linearity (low noise figure, high IP3) ensure that the initial weak RF signals are amplified cleanly and efficiently before being fed into the higher-power GaN output stages. This preserves the signal's integrity and contributes significantly to the overall system's gain and low distortion characteristics, including for complex modulated signals requiring a high-quality rf modul. -

Q: What materials are primarily used in the construction of this amplifier's housing, and why?

A: The primary material for the amplifier's housing and heatsink is typically a high-grade aluminum alloy. Aluminum is chosen for its excellent thermal conductivity, which is crucial for efficiently dissipating heat generated by the high-power RF transistors, ensuring stable operation and extended lifespan. It also offers good machinability for complex designs (CNC machining), provides effective EMI (Electromagnetic Interference) shielding, and is relatively lightweight. For demanding industrial environments (e.g., petrochemical), the housing may undergo specialized surface treatments like anodizing for enhanced corrosion resistance. -

Q: What are P1dB and IP3, and why are they important for an rf amplifier?

A: P1dB (1 dB Compression Point) is the output power level at which the amplifier's gain has compressed by 1 dB from its linear gain. It indicates the practical linear output power limit. IP3 (Third-Order Intercept Point) is a theoretical point where the power of the third-order intermodulation products (distortion) would equal the power of the fundamental signals. Both are critical measures of an amplifier's linearity, which is essential for transmitting complex modulated signals without significant distortion or interference with adjacent channels. A higher P1dB and IP3 indicate better linearity and signal fidelity. -

Q: What inspection standards does the product adhere to during manufacturing?

A: Our manufacturing processes adhere to stringent international quality standards, including ISO 9001 for quality management systems. Specific components and sub-assemblies may also comply with ANSI (American National Standards Institute) standards for electrical, mechanical, and performance characteristics. Comprehensive testing (electrical, thermal, environmental) is performed according to internal quality protocols and, for some specialized applications, in accordance with MIL-STD (Military Standard) guidelines to ensure robust performance. -

Q: What is the typical usage lifespan for this 100W solid-state power amplifier?

A: With proper operation within specified environmental and electrical parameters, our 100W Solid State High Power Amplifier is designed for an extended operational lifespan, typically characterized by a Mean Time Between Failures (MTBF) exceeding 50,000 hours. This robust lifespan is a direct result of the solid-state design, high-reliability component selection (including the grf5536), advanced thermal management, and comprehensive quality control throughout the manufacturing process. Regular maintenance and adherence to operational guidelines can further extend its service life.

Conclusion

The 100~6200MHz 100W High Gain Solid State High Power Amplifier stands as a testament to the advancements in RF technology. By integrating high-performance RFICs like the grf5536 with robust GaN power devices, we deliver a solution that offers unparalleled broadband coverage, high power, and exceptional reliability. This amplifier is not just a product; it is a critical enabler for cutting-edge applications across defense, telecommunications, test & measurement, and industrial sectors. Our commitment to quality, backed by rigorous manufacturing processes, adherence to international standards, and comprehensive customer support, ensures that our amplifiers provide superior performance and long-term value. As the demand for seamless, high-bandwidth wireless communication continues to soar, the importance of reliable, high-power rf amplifier solutions, built on the foundations of advanced components and meticulous engineering, will only continue to grow.

The ongoing innovations in solid-state technology, particularly in GaN and GaAs, are continuously pushing the boundaries of what is achievable in RF power amplification. Experts in the field emphasize the crucial balance between power, efficiency, linearity, and bandwidth. As noted in a discussion on LinkedIn's "RF & Microwave Engineering Forum," the trend towards ultra-wideband SSPAs capable of multi-octave performance is significant for emerging technologies. Furthermore, academic research highlights the importance of highly linear driver stages, often citing specific ICs for their crucial role in minimizing distortion at the system level. For example, a paper from the IEEE Microwave Theory and Techniques Society (MTT-S) International Microwave Symposium (IMS) might discuss "Advancements in Broadband GaN Power Amplifiers for 5G Applications," often mentioning the impact of low-noise, high-linearity pre-amplifiers on overall system performance. These discussions and research underpin the design philosophy behind our amplifier, demonstrating our alignment with cutting-edge industry thought.

References:

- IEEE Xplore Digital Library: https://ieeexplore.ieee.org/Xplore/home.jsp (Search for papers on "Broadband GaN Power Amplifiers" or "RF Driver ICs for Linear Amplifiers")

- LinkedIn RF & Microwave Engineering Forum: https://www.linkedin.com/groups/2959883/ (Discussions on SSPA trends and wideband RF design)

- Microwaves & RF Magazine: https://www.mwrf.com/ (Industry news and technical articles on RF power and component technology)

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 21 May 2025

-

09 March 2021 25 Dec 2024

-

09 March 2021 14 Oct 2022

-

09 March 2021 25 Dec 2024