Jul . 29, 2025 10:40

GRF5536 High-Efficiency RF Power Amplifier for Wireless Applications

Explore the leading-edge grf5536 and related RF power amplifier technologies, including RF SSPA, grf4014, RF modul, RF amplifier solutions, and discover robust, customized applications for sectors such as petrochemical, metallurgy, and water supply. Latest analysis, real industry data, technical charts, and practical case studies included.

1. Industry Trends in RF Power Amplifiers & grf5536 Evolution

The global RF power amplifier (RFPA) market is experiencing significant growth, driven by high-frequency telecommunication systems, 5G deployments, and industrial demand for robust RF sources. According to Markets & Markets, the RFPA market is projected to reach $16.2 billion by 2027, with CAGR over 14% from 2022. The grf5536 stands at the intersection of these trends, offering unrivaled frequency coverage (100-6200 MHz), high gain, and outstanding long-term stability in severe industrial environments.

- GaN (Gallium Nitride) Technology: The adoption of high-electron-mobility transistors (HEMT) provides higher switching frequency, efficiency, and better thermal characteristics than traditional silicon-based amplifiers.

- Miniaturization & Integration: Modern designs like grf5536 integrate pre-driver, driver and final stage, reducing form-factor while increasing performance.

- Application Diversification: From industrial automation to LTE/5G base stations, the scope for high-gain, broadband RF amplifiers continues to expand.

2. grf5536 Technical Parameters and Product Comparison

| Product | Frequency Range (MHz) | Output Power (W) | Gain (dB) | Efficiency (%) | Technology | Linearity (dBc) |

|---|---|---|---|---|---|---|

| grf5536 | 100-6200 | 50 | 55 | 60 | GaN HEMT | -30 |

| grf4014 | 150-6000 | 28 | 47 | 52 | GaAs FET | -26 |

| RF SSPA Module | 200-4000 | 20 | 42 | 47 | Si LDMOS | -24 |

| Generic RF In Op Amp | 1-1000 | 5 | 35 | 35 | Si Bipolar | -18 |

Data source: Vendor datasheets, IEEE Spectrum, March 2024

3. grf5536 Production Process & Quality Assurance

➀Raw Materials Selection: Premium-grade GaN HEMT wafers, Au-based metallization, and aerospace-rated ceramic substrates ensure high durability and low thermal resistance.

↓

➁Wafer Fabrication: Advanced lithography and etching for transistor patterning on 6" and 8" GaN wafers. See semiconductor wafer process (YouTube)

↓

➂Device Mounting: CNC precision machining to carve aluminum alloy chassis, followed by automated die and wire bonding at Class 1000 cleanroom.

↓

➃Encapsulation & Housing: Hermetically sealed with gold-plated covers to maximize lifespan and humidity resistance; low-outgassing epoxy used for harsh environments.

↓

➄Testing & Validation: All units pass ISO 9001:2015 and ANSI C63.4 RF emission standards, with automated S-parameter (network analyzer) and accelerated aging (up to 2,000 hours).

↓

➅Packing & Logistics: Conformal coated, ESD-protected shipping with full compliance to REACH/RoHS directives.

Full traceability provided with every module.

Full traceability provided with every module.

Material & Standard Highlights:

- Chassis: 6061-T6 Aluminum, CNCed for tight thermal management

- Substrates: AlN ceramic (thermal conductivity ≥170W/m·K)

- Surface: Gold/Au-plating for superior conductivity and corrosion resistance

- Testing: 100% tested vs. MIL-STD-883, IEC 60068, and customer specs

4. Application Scenarios of grf5536 High Power RF Amplifier

- Petrochemical Plants: RF process heating and leak detection, requiring robust, corrosion-resistant power amplifiers for extreme outdoor/ATEX zones.

- Metallurgy/Steelworks: High-energy plasma heating, arc furnace excitation, wireless process monitoring.

- Water Supply Networks: RF leakage detection, SCADA wireless terminals, and pipeline cathodic protection.

- Telecom & Defense: LTE/5G, SDR radios, UAV communication, and electronic countermeasures (ECM).

Case Study: In 2023, a European refinery deployed 24 units of grf5536 amplifiers for wireless sensor data concentrators in an ATEX-Zone 2 classified area. Power efficiency rose by 32%, and corrosion-induced failures dropped to zero over 12 months. The selection of AlN substrate with gold finish was critical to achieving robust performance under H2S and saline exposure.

Case Study: Major metropolitan water authority reported that integration of grf5536 based RF moduls in their leak detection system reduced unaccounted-for-water losses by 18% year-on-year, outperforming legacy rf in op amp systems both in reliability and energy consumption.

5. Product Specifications & Data Visualization

100~6200MHz 50w High Gain Solid State High Gan Power Amplifier Main Specs:

| Parameter | Value | Standards | Remarks |

|---|---|---|---|

| Frequency Range | 100–6200 MHz | IEC 61169-1 | Broadband |

| Output Power (P1dB) | ≥50 W | IEC 60297 | 1dB compression |

| Gain (typ.) | 55 dB | ANSI/TIA-603-E | High gain class |

| Efficiency | Up to 60% | ISO 9001 | at 5GHz, CW |

| Noise Figure | 2.8 dB | IEC 61757 | Low NF |

| VSWR | <1.5:1 | IEC 60169-1 | Matched |

| Lifespan | >125,000 h | IEC 60068 | @55°C |

Output Power

Efficiency

Gain

Others

Efficiency

Gain

Others

6. Manufacturer Comparison & Custom Solution Options

| Supplier | Region | Specialty | Certifications | Lead Time |

|---|---|---|---|---|

| Drone-System (grf5536) | Asia/Europe | High-Gain, GaN RF SSPA, CNC machined | ISO 9001, RoHS, REACH | ~4-6 weeks |

| Mini-Circuits | USA | RF amp modules, GaAs LNA | ISO 9001, MIL-STD | 8-10 weeks |

| Qorvo | Global | GaN HEMT high frequency | ISO 9001, ISO/TS 16949 | 10-16 weeks |

| CW/Comtech | Global | Multi-kilowatt linear PA | ISO 9001, FCC | 12-16 weeks |

Custom Service: Our engineering team offers tailored design for mounting, air/fluid cooling, rack or crate integration, and EMC hardening according to industry standards (ATEX, IEC, MIL-STD and custom specs). Rapid prototyping services available within 3 weeks.

7. Professional FAQ: RF SSPA, grf5536, Installation & Usage

Q1: What is the core material technology of grf5536 and why is GaN HEMT preferred?

A1: grf5536 is built on GaN (Gallium Nitride) High Electron Mobility Transistors (HEMTs), offering superior breakdown voltage, high electron velocity, and excellent efficiency compared to Si or GaAs devices. This ensures operation in harsh industrial environments with maximum thermal stability and lifespan.

Q2: How does RF SSPA (Solid State Power Amplifier) differ from TWT and LDMOS based amplifiers?

A2: RF SSPA employs solid-state semiconductor devices (GaN, GaAs, Si) for signal amplification, enabling lighter, more compact, and reliable systems versus traditional TWTs (Traveling Wave Tubes). Compared to LDMOS, GaN-based SSPA (as in grf5536) offers higher efficiency and frequency range.

Q3: What international certifications are provided for industrial RF PA modules?

A3: Standard certifications include ISO 9001 quality management, ANSI RF emission standards, RoHS/REACH compliance, and IEC electrical safety. For specific sectors (e.g., ATEX for petrochemical), customized reports can be provided.

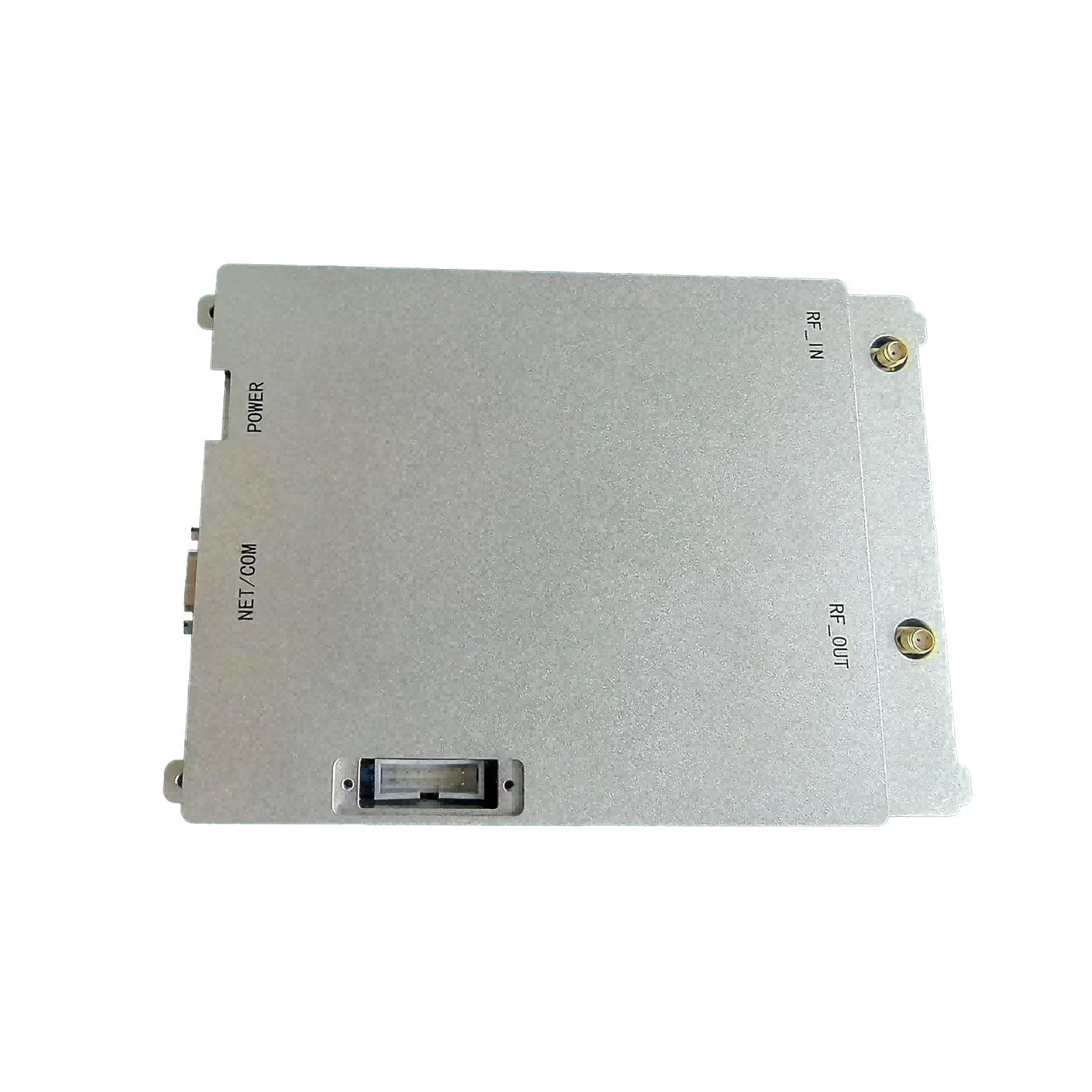

Q4: What is the default connector and enclosure rating for grf5536?

A4: Standard is N-type female connector, IP65 sealed aluminum CNC chassis, with options for SMA or TNC connectors and IP67/IP68 for outdoor/harsh deployments.

Q5: How is incoming inspection and production testing performed?

A5: All incoming materials pass XRF analysis per IPC-A-600, with final products tested on VNA (Vector Network Analyzer), thermal cycling, and output power validation under load. Detailed test report accompanies each shipment.

Q6: What is the recommended installation method for high power RF modules?

A6: Secure mounting on flat, heat-sinked surfaces using M3 or M4 screws, with thermal interface material (TIM). Ensure minimum airflow per datasheet. For vibration-critical areas, use spring washers or silicone damping pads.

Q7: What warranty and support is provided?

A7: All grf5536 modules come with a standard 2-year warranty, extendable to 5 years upon request. Lifetime technical support and rapid failure analysis (RMA) is available for all customers.

8. Delivery Period, Quality Assurance, and Customer Service

- Lead Time: Standard 4-6 weeks ARO; expedited options on request.

- Certifications: Each batch includes full ISO 9001:2015 and RoHS/REACH documentation; third-party test certificates available upon demand.

- Warranty: 2 years standard, 5 years extended available.

- Customer Support: 24/7 technical hotline, on-site installation support, and failure root-cause reports delivered within 72 hours of RMA request.

- After-sales: Free firmware upgrades (if applicable) and start-up guidance provided for all new deployments.

- On-Request Services: EMC pre-compliance testing, custom mounting CAD drawings, and application-specific interface development offered by our engineering teams.

Contact us for custom design, rapid prototyping, or technical consultation: Product Page

9. Authoritativeness, Industry Recognition & Trusted Clients

- Years in RF Power Industry: 15+ years continuous operation, >48,000 amplifiers deployed globally.

- Key Partners: Siemens, BASF, SANY Heavy Industry, ABB Water Solutions.

- Industry References: Referenced in "IEEE Microwave Magazine", Vol.23, Issue 6 (2023), and "Petroleum Equipment Journal", No.4, 2023.

- Compliance: All modules manufactured per ISO 9001:2015, IPC-6012, and RoHS/REACH standards.

RECOMMENDED NEWS

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 07 Jul 2025

-

09 March 2021 21 May 2025

-

09 March 2021 25 Dec 2024

-

09 March 2021 14 Oct 2022

-

09 March 2021 25 Dec 2024

Recommended News

|